P0345 Code: Tackling Camshaft Position Sensor Faults Problems

P0345 Code: Tackling Camshaft Position Sensor Faults Problems

Have you ever encountered the dreaded Check Engine Light with code P0345? You’re in the right place!

In this guide, we’ll explore everything you need to know about this code, including its meaning, symptoms, and causes. But that’s not all – we’ll also provide you with the knowledge and expertise to diagnose and fix the problem like a pro.

So, let’s get started!

P0345 Code: Quick Overview

But first, let’s take a look at the P0345 code overview!

Definition: Camshaft Position Sensor A Circuit Malfunction (Bank 2)

Severity: High

DIY Skill Level: Advanced

Continue To Drive?: No

Estimated Repair Cost: $50 – $200

What Does the P0345 Code Mean?

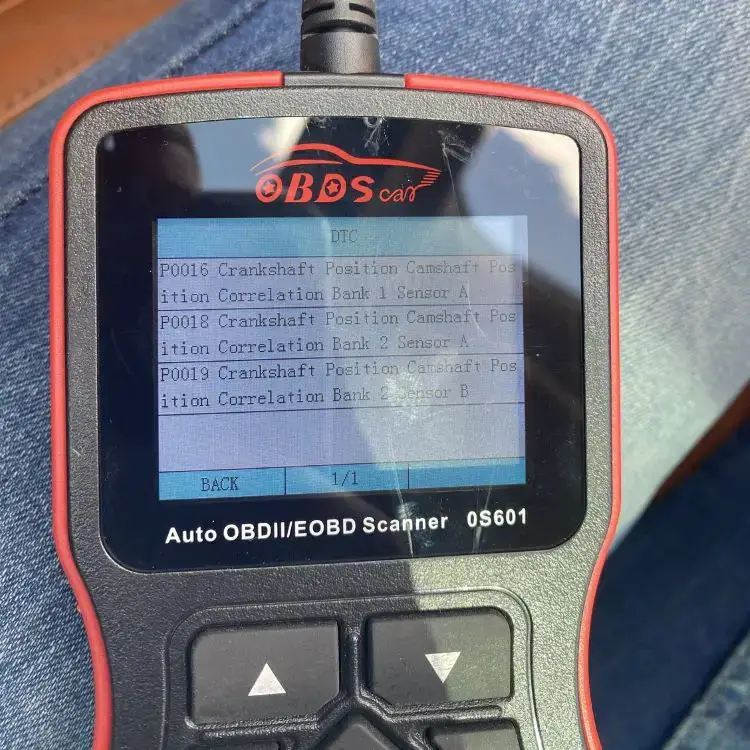

The P0345 diagnostic trouble code (DTC) indicates a camshaft position sensor A circuit malfunction in Bank 2. This code is commonly found in Nissan, Ford, Infiniti, and Lexus car models.

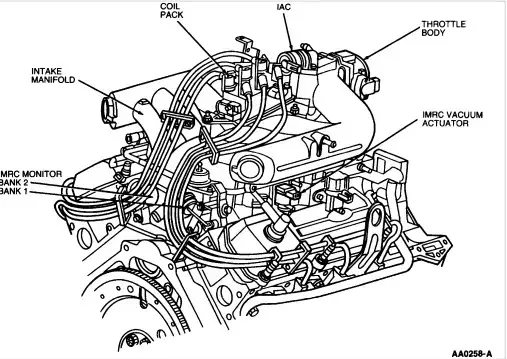

In modern vehicles, the engine’s camshaft plays a crucial role in the precise timing of the intake and exhaust valves. The camshaft position sensor, located near the camshaft, monitors the position and speed of the camshaft. This sensor sends the recorded information to the engine control module (ECM), which uses it to determine the optimal fuel injection and ignition timing.

When the camshaft position sensor A circuit in Bank 2 malfunctions, the ECM doesn’t receive the expected signals from the sensor. As a result, the code P0345 will be set.

This code is often associated with other DTCs like P0340 (Camshaft Position Sensor A Circuit Malfunction Bank 1), P0344 (Camshaft Position Sensor Circuit Intermittent), and P0349 (Camshaft Position Sensor A Circuit Intermittent Bank 2). These codes may share similar causes and symptoms, making it important to diagnose and address them collectively for a comprehensive repair.

Read more: P0340 – Camshaft Position Sensor “A” Circuit

How Serious is the P0345 Code?

The P0345 code is considered a high severity level as it can lead to significant issues, including potential no-start situations that may leave you stranded. While it may not cause immediate breakdown or safety hazards, it is crucial to address the issue promptly to avoid potential engine performance problems and further complications.

Continuing to drive with the P0345 code can be risky as it may lead to serious issues such as stalling, misfires, or poor acceleration. To ensure safe driving conditions and prevent potential engine damage, it is strongly recommended to diagnose and repair this problem as soon as possible.

Symptoms of the P0345 Code

You can observe various symptoms when the P0345 trouble code appears, including:

- Check Engine Light, traction control, and/or “Check VSC” light illuminated

- Engine misfires or runs roughly

- Decreased engine power and performance

- Hesitation or stumbling during acceleration

- Engine stalling or difficulty starting

- Poor fuel efficiency

What Causes The P0345 Code?

Possible causes of P0345 may include:

- Faulty/Contamination camshaft position sensor

- Wiring or connector issues in the sensor circuit

- Sensor alignment or synchronization problems

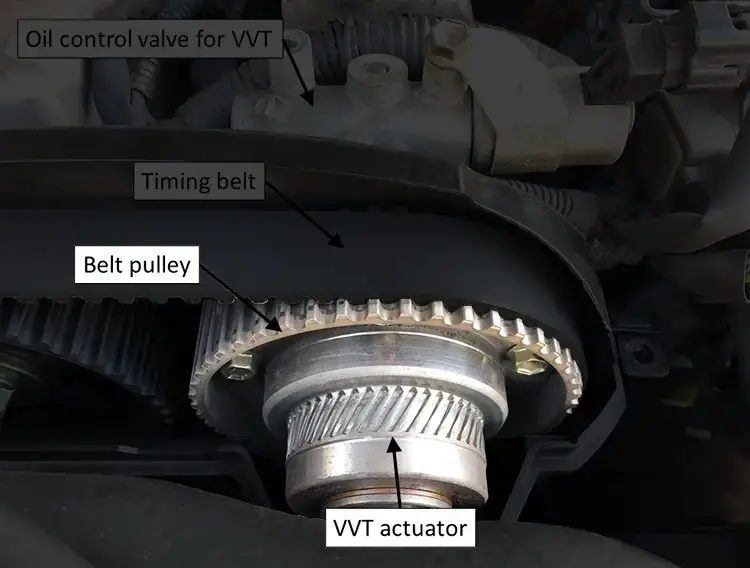

- Timing belt/chain problems affecting the camshaft’s position

- Bad crankshaft position sensor

- Electrical problems such as a short or open circuit

- ECM or PCM software issues

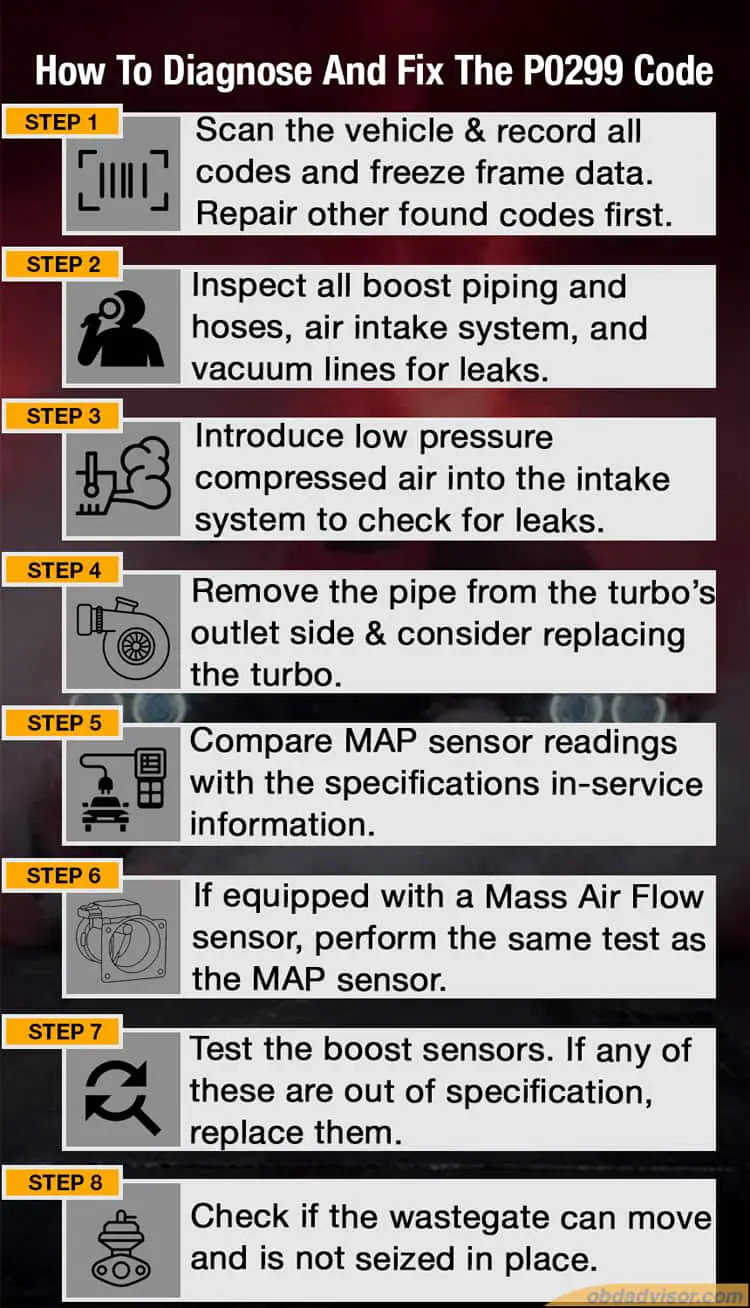

How To Diagnose And Fix The Code P0345

Now, it’s time to explore the diagnosis and repair process. In this section, we’ll guide you through the necessary tools and parts, outline a step-by-step procedure, and discuss the level of DIY repairs you can undertake. By following this guide, you can save money on repairs and better understand your vehicle’s problem.

Essential Tools and Parts

To diagnose and repair the P0345 trouble code, you may need the following tools and parts:

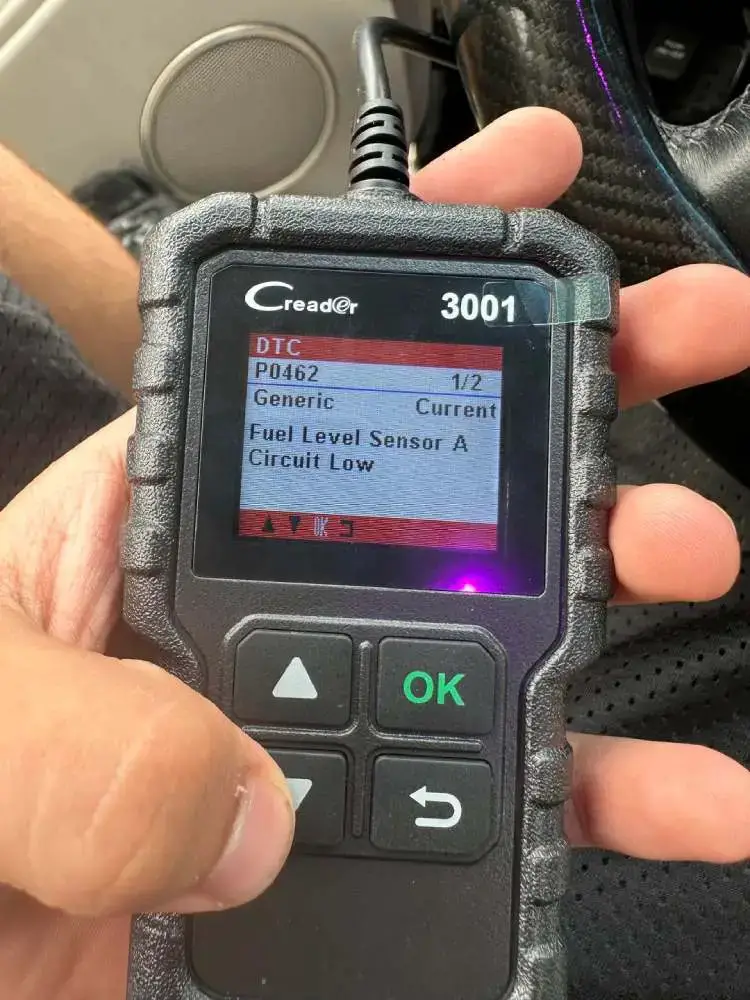

- OBD-II scanner or code reader

- Multimeter

- Basic hand tools (screwdrivers, wrenches, sockets)

- Camshaft position sensor

- Crankshaft position sensor

- Wiring connectors and terminals

- Electrical tape or heat shrink tubing for wire repairs

- MAF sensor cleaner spray

Step-by-Step Procedure

- Connect the OBD-II scanner or code reader to the vehicle’s diagnostic port to retrieve the stored trouble code.

- Inspect the wiring and connectors related to the camshaft position sensor in Bank 2 for any visible damage or loose connections.

- Check the camshaft position sensor for any dirt or corrosion. Clean it if needed.

- If no apparent issues are found, use a multimeter to test the resistance and voltage of the sensor and its circuit. Compare the readings obtained to the manufacturer’s specifications.

- If the sensor is faulty, replace it with a new one, ensuring proper alignment and secure connection.

- Test the crankshaft position sensor voltage if the camshaft sensor works properly. If the reading is different from the manufacturer’s specifications, replace it.

- Perform a PCM test if the above steps cannot help you fix the P0345 code.

- Clear the trouble code and test drive to ensure the issue has been resolved.

Notes:

- Before replacing the camshaft position sensor, keep the engine cool to avoid potential burns.

- Take caution when working with electrical connections and wiring to prevent short circuits or damage.

- Refer to the vehicle’s service manual or online resources for specific instructions and component locations.

DIY Repair Level and Estimated Costs

The repair level for diagnosing and resolving the P0345 code can vary depending on an individual’s mechanical expertise. While some DIY enthusiasts with experience in automotive repairs may successfully tackle this task, it is recommended to seek professional assistance if uncertain.

Here is a table providing a general overview of the estimated costs:

| Repair Task | Estimated Cost Range |

| Camshaft position sensor repair/replacement | $50 – $250 |

| Wiring connectors and terminals | $50 – $100 |

| Professional Diagnostic Fee | $50 – $150 |

Please note that these costs are approximate and can vary significantly. It’s always recommended to consult with a trusted mechanic or automotive service center to obtain accurate cost estimates based on your specific vehicle and location. Their expertise and guidance can ensure a proper diagnosis and cost-effective resolution of the P0345 code.

Final Thoughts

You’re now gaining a comprehensive understanding of the P0345 trouble code and its implications for your vehicle’s performance! With this knowledge, you can now tackle the challenges of dealing with a camshaft position sensor A circuit malfunction in Bank 2.

Remember, timely diagnosis and repair are crucial to maintaining your vehicle’s optimal performance and avoiding further complications. If you’re confident in your DIY skills, go ahead and address the issue using the step-by-step guide provided. However, if you’re unsure or encounter difficulties, don’t hesitate to seek professional assistance from a trusted mechanic.

Additionally, take advantage of our OBD Code List Generator to find specific code lists, or use our OBD code lookup tool for instant reference.

We hope this guide has been helpful to you. Feel free to share your thoughts or ask questions in the comments below. Safe driving and happy repairing!

Reference:

- Camshaft – Wikipedia

- Understanding Camshaft Position Sensor – studentlesson.com

- Variable Valve Timing (VVT) – austincc.edu

C0265 Chevy Code: Your ABS Repair Guide

C0265 Chevy Code: Your ABS Repair Guide

When your Chevy vehicle shows the C0265 code, it can be confusing. While this trouble code might lead many to assume that the entire control module is at fault, the actual culprit lies in a specific component within the Electronic Brake Control Module (EBCM).

This can be a bit of a head-scratcher for Chevy owners. But don’t worry, we’ll help you understand it better. In this article, we’re going to take a closer look at the C0265 code.

If you’ve ever wondered about this code, keep reading to learn more.

C0265 Chevrolet: A Quick Summary

Look at the overview of the C0265 Chevy code.

- Definition: EBCM Motor Relay Circuit Low When On

- Severity: Medium

- DIY Skill Level: Beginner

- Continue To Drive?: Yes

- Estimated Repair Cost: $20 – $200

What Does The C0265 Mean In Chevy Vehicles?

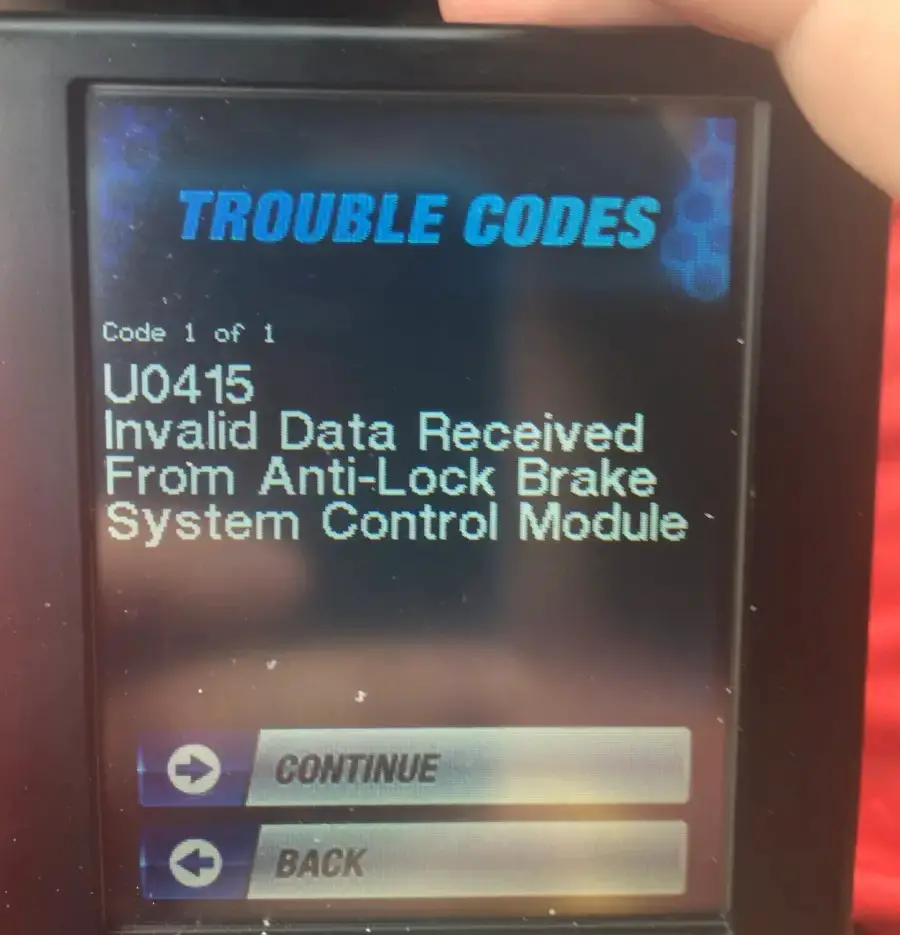

In Chevy and GMC vehicles, this C0265 code is primarily triggered by a faulty connection at the EBCM ground, which is situated inside the module itself, not the whole EBCM. This ground issue affects the proper functioning of the anti-lock braking system (ABS).

The EBCM is a vital component of the ABS in Chevrolet and GMC vehicles. It serves as the brain behind ABS operations, responsible for regulating and optimizing braking performance. Inside the EBCM, a complex system of sensors and circuits constantly monitors wheel speed and makes rapid adjustments to prevent wheel lockup during hard braking, enhancing vehicle stability and control.

U1041 is commonly set along with C0265, this code indicates a potential loss of communication with the brake module. The C0265 code is predominantly found in various Chevrolet models. Some commonly affected models include the Silverado, Tahoe, Suburban, S-10, and Trailblazer.

How Serious Is The C0265 Chevrolet Code?

The severity of the C0265 Chevy code is moderate. While it doesn’t demand an immediate halt to driving, it shouldn’t be ignored. Continuing to drive with this code may reduce ABS effectiveness, potentially compromising safety. Our advice is to address it promptly. While it’s generally safe to continue driving, get it checked and fixed soon to ensure your ABS functions correctly.

Read more: C0265 Chevy Code: Throttle Position Sensor Issues Explained

What Are The Signs Of The C0265 Chevy Code?

Here are some common signs of C0265 in Chevrolet vehicles:

- Illuminated Check engine light, ABS warning light, or Park brake warning light on the dashboard

- Defective traction control system

- Reduced braking performance

- Difficulty accessing the 4WD

What Are The Causes Of The C0265 Code In Chevrolet Vehicles?

The C0265 code can be triggered by several underlying causes. Here are the primary culprits:

- Poor connection at the EBCM ground (specific to each vehicle type):

- Midsize Chevy/GMC vehicles: Ground 304

- Chevy SSR: Ground 400

- Full-size trucks and utility vehicles: Ground 110

- Corrosion or damage to wiring and connectors

Read more: P1345 Chevy: Meaning, Symptoms, Causes and Fixes

How To Diagnose And Repair C0265 Chevrolet Code?

When dealing with the C0265 Chevy code, proper diagnosis and repair are essential. Here’s what you’ll need and a step-by-step guide to tackle this issue.

Diagnostic Tools And Essential Parts

To diagnose and repair the C0265 Chevy code, you may need the following tools and parts:

- OBD scanner

- Soldering iron and solder

- Wiring diagram for your specific vehicle

- Wire brush or sandpaper for cleaning

- Basic hand tools (screwdrivers, pliers)

Step-by-Step Guide

- Code retrieval: Connect a scan tool or OBD-II code reader to retrieve the C0265 and any additional codes.

- Safety first: Ensure the vehicle is on a level surface, the ignition is off, and you’ve disconnected the battery.

- Locate EBCM: Find the EBCM in your vehicle. Refer to your wiring diagram if needed.

- Access EBCM: Carefully open the EBCM unit to access the circuit board inside.

- Identify ground points: Locate the specific ground point causing the issue. Refer to your vehicle’s documentation for the correct ground reference.

- Soldering: Gently solder the problematic ground point. Ensure a strong and secure connection.

- Clean surrounding area: Clean the surrounding area to remove any corrosion or dirt that may have contributed to the problem.

- Reassemble: Close the EBCM unit and reattach it securely.

- Reconnect battery: Reconnect the vehicle’s battery and start the engine to check if the ABS warning light is off.

- Test drive: Take a short test drive to ensure the ABS system is functioning correctly.

C0265 Chevy Code: DIY Repair Level And Estimated Costs

This repair is kind of easy for a DIY-er. It falls into the DIY category for those with moderate soldering skills and access to necessary tools. If you’re unsure about soldering or face difficulties, it’s wise to consult a professional mechanic.

The estimated cost for fixing the C0265 code can vary depending on whether you DIY or have it done by a mechanic. Here is a general cost breakdown:

| Repair Task | Estimated Cost |

| Soldering equipment and materials | $20 – $50 |

| Professional mechanic (if needed) | $100 – $200 |

Remember that prices may vary depending on your location and specific vehicle model.

Read more: P1101 Intake Air Flow System Performance in Chevy Cruze Vehicles

Conclusion

Now, you’ve gained valuable insights into the C0265 Chevy code’s diagnostics and repairs. Armed with this knowledge, you can now tackle this code with confidence, ensuring that your vehicle’s Anti-Lock Brake System operates at its best.

If you found this article helpful, consider sharing it with fellow Chevy and GMC owners who might be facing similar challenges.

Have you encountered the C0265 code before, or do you have additional tips to share? Drop a comment below.

Reference Sources

- General Motors, GM Technical Service Bulletin on ABS Code C0265.

- MyCarDoesWhat.org, Anti-Lock Braking System.

- YourMechanic.com, Symptoms of a Bad or Failing Traction Control Module.

P051B Code: A Comprehensive Guide for Vehicle Owners

P051B Code: A Comprehensive Guide for Vehicle Owners

Welcome, vehicle owners! If you’ve encountered your vehicle’s P051B error code, you’ve arrived at the right place.

In this guide, we’ll explore the details of the P051B code, its meaning, severity, symptoms, causes, and the necessary diagnosis and repair steps. As experienced mechanics with a wealth of knowledge, we’re here to share our expertise and assist you in resolving this issue.

So, let’s dive in!

P051B Code: Quick Overview

Here is an overview of the P051B code. Take a look!

Definition: Crankcase Pressure Sensor Circuit Range/Performance

Severity: High

DIY Skill Level: Intermediate

Continue To Drive?: No

Estimated Repair Cost: $100 – $300

What Does The P051B Mean?

The P051B error code indicates a problem with the Crankcase Pressure Sensor Circuit Range/Performance. This code is commonly found in various car brands, including Ford equipped with EcoBoost engines, Dodge with Cummin engines, etc.

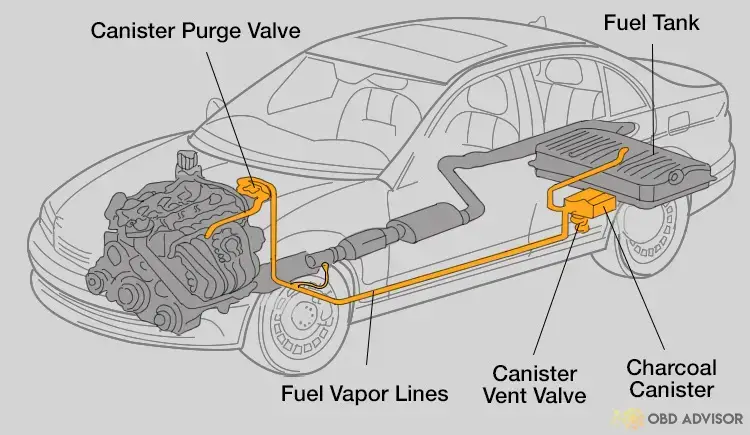

The Crankcase Pressure Sensor is an essential part of the vehicle’s emission control system. It works with the Positive Crankcase Ventilation (PCV) system, which manages the pressure and circulation of gases within the engine crankcase.Under normal operating conditions, the Crankcase Pressure Sensor monitors the pressure levels within the crankcase. If the sensor detects that the pressure deviates from the expected range, it sends a signal to the engine control module (ECM) or powertrain control module (PCM), triggering the P051B error code.

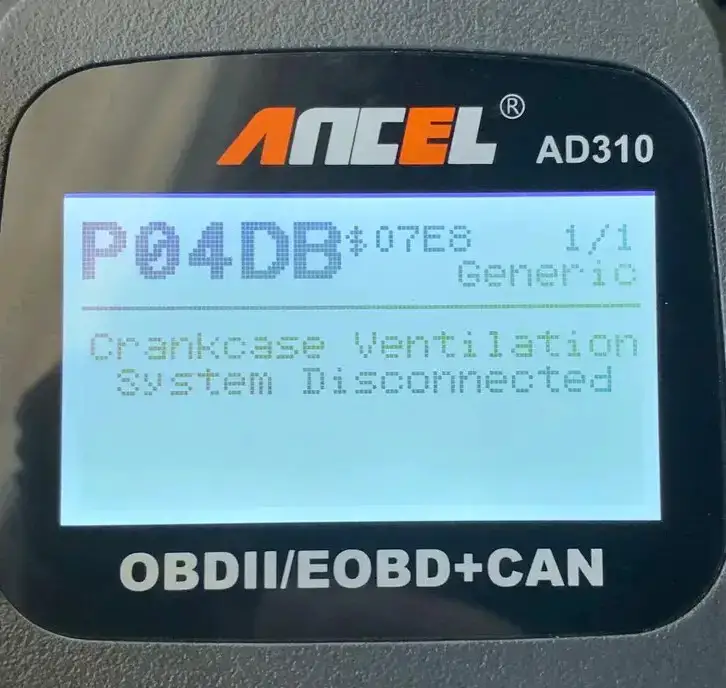

It’s worth noting that the P051B code is often associated with code P04DB, which indicates a problem with the Crankcase Ventilation System Disconnected. These codes are closely related, as a malfunction in the crankcase ventilation system can impact the sensor’s readings, leading to the P051B code being triggered.

Is it Safe to Continue Driving With The P051B?

The P051B code is considered to be of high severity level. Ignoring or continuing to drive with the P051B code can have severe consequences, including engine performance degradation, reduced fuel efficiency, and the risk of further damage to crucial engine components.

It is crucial to address this code promptly to prevent further complications and ensure your vehicle’s safe and optimal operation. We strongly advise against driving with the P051B code present and diagnosis and repair as soon as possible.

Signs of The P051B Code

The following are common symptoms associated with the P051B error code:

- Illuminated Malfunction Indicator Lamp (MIL) or Check Engine Light

- Reduced engine performance or power

- Engine misfires or rough idle

- Decreased fuel efficiency

What Triggers the P051B Code?

The P051B error code can be caused by various factors, including:

- Engine over-filled with oil

- Faulty or malfunctioning crankcase pressure sensor

- Dirty/bad positive crankcase ventilation valve

- Water intrusion in crankcase pressure sensor

- Issues with the wiring or connectors related to the sensor

- Crankcase ventilation system problems: broken hoses, blown valve cover gasket, failed oil fill cap, v.v

- PCM or ECM software or programming issues

How To Diagnose And Fix The P051B Code

In this section, we will provide you with the necessary tools and parts required for diagnosing and repairing the P051B error code. We will then guide you through a step-by-step procedure to address the issue effectively.

Essential Tools and Parts

- OBD-II scanner or code reader

- Basic hand tools (such as wrenches, sockets, and screwdrivers)

- Crankcase pressure sensor (if necessary)

- Positive crankcase ventilation valve

- Vacuum hose/connector

- Electrical connectors and wiring repair kit

Step-by-Step Procedure

- Retrieve Diagnostic Trouble Codes:

Connect an OBD-II scanner or code reader to retrieve the trouble codes and identify the P051B code.

- Check the engine oil:

Use the dipstick to check the engine oil. Make sure it’s not overfilled. Drain the excess oil if needed.

- Visual inspection of the Positive Crankcase Ventilation (PCV) System:

- Inspect the PCV valve, hoses, and connections for any signs of leaks, damage, or restrictions. Ensure that the PCV valve maintenance schedule has been followed.

- Verify that the correct PCV valve part number is being used.

- Check the cleanliness and correct routing of the fresh air tube and related hoses.

- If any concerns are found during the inspection, repair or replace the affected components.

- Check for Leaks:

- Inspect the oil cap, throttle body, PCV hose, vacuum lines and the air intake system for any leaks or damages.

- Repair or replace the faulty parts if needed.

- Inspect the wiring and connectors related to the crankcase pressure sensor:

- Inspect the wiring and connectors related to the crankcase pressure sensor for any visible damage, loose connections, or corrosion.

- If wiring issues are found, repair or replace the damaged wiring and ensure proper connections.

- Test the Crankcase Pressure Sensor:

- Use a multimeter to test the crankcase pressure sensor. Ensure to consult the manufacturer’s specifications for testing procedures.

- If the reading is out of range, replace it with a new one and make sure proper installation.

- Clear code and test drive:

Clear the error codes using the OBD-II scanner and test the vehicle to verify if the P051B code reoccurs.

Note: It is recommended to consult the vehicle’s service manual or seek professional guidance for specific instructions and testing procedures tailored to your vehicle’s make and model.

DIY Repair Level And Estimated Costs

The level of DIYer skill required to address the P051B error code can vary from immediate to advanced. It is important to consider your mechanical skills and experience when deciding whether to tackle the diagnosis and repair yourself.

While some individuals may feel confident in performing the diagnosis and repair themselves, others may prefer to seek assistance from a professional mechanic. It is important to assess your capabilities and comfort level before proceeding with DIY repairs.

Below is a table of estimated costs for repairing the P051B error code:

| Repair Task | Estimated Cost Range |

| Crankcase Pressure Sensor Replacement | $50 – $200 |

| Wiring Repair | $50 – $200 |

| Vacuum Leak Repair | $100 – $300 |

| Professional Diagnostic Fee | $75 – $150 |

Please note that these estimated costs are intended to provide a general idea and can vary depending on the vehicle make and model, location, and labor rates. It’s always recommended to consult local mechanics or obtain quotes from automotive repair shops to get a more accurate estimate tailored to your situation.

Final Thoughts

Now, you have a comprehensive understanding of the P051B error code and how to address it. By recognizing the symptoms, understanding the causes, and following the step-by-step repair procedure, you are equipped to tackle this issue confidently. Remember, it is crucial to address the P051B code promptly to prevent further complications and ensure the safe operation of your vehicle.

If you found this guide helpful, feel free to share it with other car enthusiasts who may benefit from this knowledge. We also encourage you to leave your comments or questions below. Your feedback is valuable, and we’re here to provide further assistance or clarify any doubts you may have.

Keep your vehicle running smoothly and stay informed about other car-related topics. Safe travels!

Reference:

Howstuffworks – How Does a Positive Crankcase Ventilation (PCV) System Work?

P06DD Code: Causes, Diagnosis, and Repair Explained

P06DD Code: Causes, Diagnosis, and Repair Explained

If you’ve encountered the P06DD code in your vehicle, there’s no need to worry. I’ll guide you through the meaning of the P06DD code, discuss possible causes, and offer step-by-step instructions for diagnosing and fixing the problem.

Whether you’re a DIY enthusiast or simply seeking knowledge before visiting a mechanic, this article is here to assist you. Let’s explore the details of the P06DD code and get your vehicle back on the road smoothly.

P06DD Code: A Quick Overview

Take a look at a P06DD code’s quick summary!

- Definition: Engine Oil Pressure Control Circuit Stuck Off

- Severity: Medium

- DIY Skill Level: Intermediate

- Continue To Drive?: No

- Estimated Repair Cost: $20 – $600

What Does The P06DD Code Mean?

The P06DD diagnostic trouble code (DTC) is defined as “Engine Oil Pressure Control Circuit Stuck Off” and refers to a detected issue in the engine oil pressure control system. In this scenario, the engine oil pressure sensor is sending a message to the Powertrain Control Module (PCM), indicating that the oil pressure is below the acceptable level, thereby impacting the normal operation of the oil pump.

The engine oil pump plays a crucial role in ensuring a consistent oil pressure supply. It functions with two pressure stages under regulation, which are governed by an on/off solenoid. The low-pressure mode, with the solenoid on, maintains a pressure of approximately 200 kPa (29 psi). Conversely, the high-pressure mode, with the solenoid off, increases the pressure to around 450 kPa (65 psi).

The minimum required pressure for the engine, under all operating conditions, is typically around 41 kPa (6 psi). When the oil pressure sensor indicates low oil pressure where higher pressure is expected, or if there is damage to the oil pump face, the PCM takes precautionary measures to reduce engine wear. It disables the oil pump drive and generates the P06DD code as an alert.

While the P06DD code can potentially occur in various vehicle makes and models, it is more commonly observed in certain brands. Some of the manufacturers that have reported instances of the P06DD code include: Dodge, Jeep, Chevrolet, Chrysler, etc.

In some cases, the P06DD code may be accompanied by additional diagnostic trouble codes, providing further insights into the underlying issue. Some of the common accompanying codes may include: P0521, P0522, P0523, and P06DE.

Read more: Dodge, Chrysler, and Jeep OBD1 Codes and OBD2 Codes

How Serious Is The P06DD Code?

The severity level of the P06DD code is moderate to high. Ignoring this code and continuing to drive the vehicle can potentially lead to serious engine damage. Insufficient oil pressure can result in poor lubrication, increased friction, and accelerated wear on engine components. Over time, this may cause engine overheating, decreased performance, and even complete engine failure.

If the P06DD code is detected, it is strongly advised not to continue driving the vehicle. Immediate attention from a qualified technician is necessary to diagnose and resolve the underlying issue. Continuing to drive with low oil pressure can have severe consequences and may result in costly repairs. It is crucial to address the problem promptly to ensure the longevity and reliability of the engine.

What Are The Symptoms Of The P06DD Code?

The P06DD code can manifest through the following symptoms:

- Illuminated Check Engine Light

- Low oil pressure warning light or message

- Engine misfires or runs roughly

- Engine overheating

- Loss of power or reduced engine performance

- Noise from the engine

What Are The Causes Of The P06DD Code?

The P06DD code can be caused by various factors, including:

- Engine oil level or quality issues

- Faulty oil pressure sensor

- Malfunctioning oil pump

- Clogged oil passages or filters

- Wiring or connector issues in the oil pressure control circuit

- PCM or software-related problems

How To Diagnose And Repair P06DD Code?

In this section, we will outline the essential tools and parts required for diagnosing and repairing the P06DD code, followed by a step-by-step procedure.

Diagnostic Tools And Essential Parts

To diagnose and repair the P06DD code, you may need the following tools and parts:

- OBD-II scanner or code reader

- Multimeter

- Oil pressure gauge

- Engine oil

- Basic hand tools (wrenches, sockets, etc.)

- Replacement oil pressure sensor (if necessary)

- Replacement oil pump (if necessary)

Step-by-Step Guide

- Retrieve and evaluate trouble codes

Connect the OBD-II scanner or code reader to retrieve the P06DD code and any additional relevant codes.

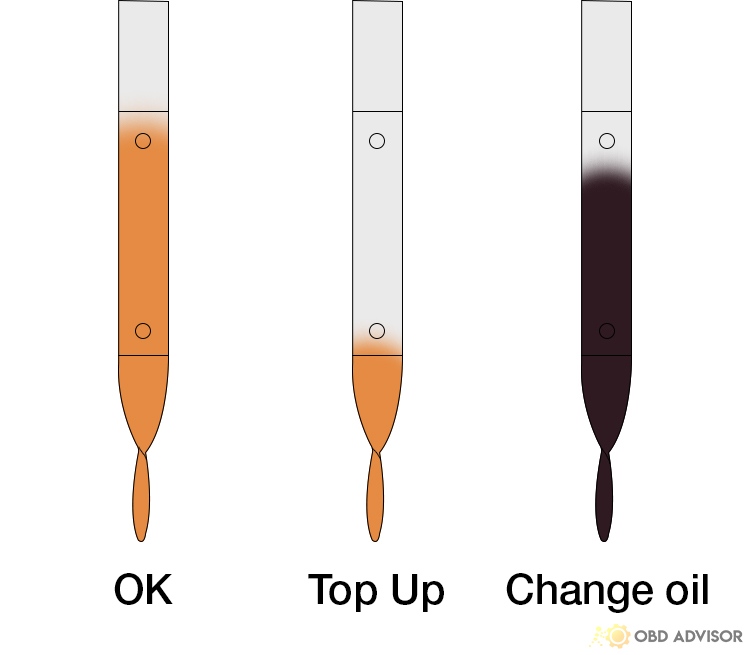

- Check engine oil level and quality

- Check the engine oil level and ensure it is at the recommended level.

- Inspect the oil quality and consider replacing it if it appears contaminated or degraded.

- Inspect oil pressure sensor and wiring

- Inspect the oil pressure sensor and its wiring for any signs of damage, corrosion, or looseness.

- Ensure proper connection and secure any loose wiring or connectors.

- Test oil pressure sensor

- Using a multimeter, test the oil pressure sensor to determine if it is functioning correctly.

- Follow the manufacturer’s specifications for the sensor’s resistance values and compare them to the measured readings.

- If the sensor goes faulty, consider replacing it.

- Inspect oil passages and filters

- Inspect the oil passages and filters for blockages, restrictions, or debris.

- Clean or replace any clogged filters and ensure proper oil flow through the passages.

- Measure actual oil pressure

- Use an oil pressure gauge to measure the actual oil pressure and compare it to the manufacturer’s specifications.

- Ensure that the measured pressure falls within the acceptable range for the engine.

- If any parts become defective, such as an oil pump, repair or replace it.

- Clear the code and test drive

- Use the OBD-II scanner to clear the P06DD code.

- Take the vehicle for a test drive to ensure the issue is resolved and the code will not reappear.

Note:

- Ensure the engine is cool before performing any diagnostic or repair work.

- Refer to the vehicle’s service manual for specific instructions and torque specifications.

- Take caution when working with hot or pressurized oil to prevent injury.

DIY Repair Level And Estimated Costs

Performing the fixing procedure for the P06DD code may require intermediate DIY skills. Tasks such as using specialized tools, inspecting components, and replacing parts can be complex. If you have intermediate skills and feel comfortable, you can attempt the repair.

Otherwise, it’s advisable to seek assistance from a professional mechanic to ensure proper repairs and avoid complications. Prioritizing safety and the proper functioning of your vehicle is important.

Here’s an estimated cost table for the repair tasks associated with resolving the P06DD code:

| Repair Task | Estimated Cost |

| Wiring issues repair | $100 – $300 |

| Oil top up | $20 – $50 |

| Oil pump replacement | $300 – $800 |

| Oil pressure sensor replacement | $50 – $150 |

| Oil passages and filters replacement | $100 – $300 |

Please note that these estimated costs are rough estimates and can vary depending on various factors such as the location, vehicle make and model, and the specific parts and labor rates charged by mechanics or repair shops.

Conclusion

Ready to address the P06DD code in your vehicle? Equipped with the information provided, you can now approach the diagnosis and repair of this issue with confidence. Don’t hesitate to share this valuable knowledge with fellow car enthusiasts who might be encountering similar challenges.

If you have any questions or success stories to share, we’re here to listen. Feel free to leave your comments below.

Reference Sources

- Welland Power, What is an Oil Pressure Sensor? How to test an oil pressure sensor?

- Professional Auto Repair, What is engine misfiring?

P0A80 Code: Hybrid Battery Insights And Resolutions

P0A80 Code: Hybrid Battery Insights And Resolutions

Welcome to our comprehensive guide on dealing with the P0A80 error code – a common challenge faced by hybrid vehicle owners. As technology propels us into a more sustainable automotive era, understanding and troubleshooting hybrid-specific issues has become essential.

In this article, we’ll clarify the P0A80 code, equipping you with the knowledge and tools needed to diagnose and address potential hybrid battery pack issues. Whether you’re a DIY enthusiast or seeking expert assistance, our step-by-step insights aim to tackle the problem easily.

Let’s dive in!

P0A80 Code: A Quick Overview

Check the summarized details of the P0A80 code presented below!

- Definition: Replace Hybrid Battery Pack

- Severity: High

- DIY Skill Level: Advance

- Continue To Drive?: No

- Estimated Repair Cost: $50 – $2000 (It will be much more costly if you replace the full battery pack)

What Does The P0A80 Code Mean On?

Error code P0A80 indicates a problem with the hybrid battery pack’s balancing or deterioration, specifically in vehicles equipped with nickel-metal hydride (NiMH) battery technology.

P0A80 is often referred to as the “Replace Hybrid Battery Pack” code. It generally means that the battery pack’s modules are not properly balanced in terms of capacity or voltage, leading to reduced performance and efficiency of the hybrid system. This code is commonly seen in older hybrid vehicles as their battery packs age and the cells within them degrade.

This code is like a message from a hybrid car’s computer that something might be off with its battery. Imagine the battery is made of blocks, and each block has cells. If the voltage difference between these blocks is more than 20% which is detected by the battery monitoring system (BMS), the code would be set.

In addition to the P0A80 code, there are often accompanying codes that provide further insight into the specific nature of the problem. These codes help technicians pinpoint the exact issue and provide a more comprehensive diagnosis. Some of the accompanied codes commonly observed with the P0A80 code include P0A7F, P3006, P3012, etc.

The P0A80 code is frequently encountered in various hybrid and electric vehicle models, spanning a range of brands. Some of the notable brands and models that are known to experience this code include:

- Toyota Prius

- Honda Insight

- Ford Fusion Hybrid

- Chevrolet Volt

- Nissan Leaf

- Hybrid Lexus models

How Severe Is Code P0A80?

The P0A80 error code’s severity is high. Because this issue is related to the hybrid battery pack, which plays a vital role in a hybrid vehicle.

Can you drive with the P0A80 code unresolved? – It’s advised to avoid prolonged driving and seek professional assistance promptly. Operating the vehicle with an imbalanced or deteriorated battery pack could escalate the issue, potentially resulting in higher repair costs. To ensure safety and prevent further damage, consult a certified mechanic or dealership as soon as possible to diagnose and address the problem effectively.

What Are The Symptoms Of The P0A80 Codes?

Experiencing certain symptoms can provide crucial insights into the nature of error code P0A80. These indicators may point toward issues within the hybrid battery system that require attention.

Here is the list of the P0A80 code’s symptoms:

- Reduced fuel efficiency

- Poor hybrid system performance

- Warning lights on the dashboard

Read more: Complete Toyota OBD1/OBD2 Codes List [FREE DOWNLOAD]

What Causes the P0A80 Code to be Set?

Understanding the potential causes behind error code P0A80 is essential for effective diagnosis and repair. Several factors can contribute to the triggering of this code, each shedding light on possible sources of the problem within the hybrid battery system.

- Aging battery cells or pack

- Corrosion on the voltage sensor harness/bus bars

- Debris in the HV battery cooling fan

- Voltage difference between battery blocks

- Excessive cell resistance

How To Diagnose And Fix The P0A80 Code?

Efficiently addressing error code P0A80 requires accurate diagnosis and appropriate repairs. Here’s a comprehensive guide to help you navigate the process.

Essential Tools And Parts

To successfully diagnose and repair the P0A80 code, you’ll need the following tools and parts:

- OBD-II scanner

- Multimeter

- Cleaning supplies for sensor harnesses and bus bars

- A source of HV battery diagnostic information

- Replacement battery pack (if required)

Step-by-Step Procedure

- Retrieve codes and freeze frame data

Use the scanner to retrieve stored codes and relevant freeze frame data. Take note of essential information for analysis.

- Visually inspect for any corrosion and defective components

Inspect the HV battery pack and circuitry for signs of corrosion, damage, or open circuits. Clean and repair areas with corrosion. Replace defective components.

- Check the HV battery cooling fan

Check the fan for debris and ensure it’s clean.

- Test hybrid vehicle battery monitoring system (HVBMS) sensors

Follow manufacturer specifications to test HVBMS sensors, such as temperature and voltage sensors. Replace if necessary.

- Check individual cell resistance

Utilize the DVOM to test individual HV battery cells for resistance. Replace cells with unacceptable resistance levels.

- Test busbar and cable

Test resistance in busbar connectors and cables using the DVOM. Replace components with excessive resistance.

- Consider HV battery pack replacement

If extensive inconsistencies persist, consider replacing the entire HV battery pack for a more reliable fix.

- Reassess

Clear the code and test drive procedure after making repairs to ensure the issue is resolved.

Note:

- Remember to disconnect the vehicle’s 12V battery before starting any work.

- For the replacement of the battery pack, it’s strongly recommended to entrust this task to a skilled mechanic with experience in hybrid vehicles to ensure a safe and proper installation.

- If your car’s odometer is over 100,000 miles, a worn battery pack could be the culprit. In case the mileage is below 100,000, the issue might involve wiring or other components. Recognizing this early could save you a fortune by knowing when to replace the battery pack. Keep these factors in mind during diagnosis.

Read more: Nissan Trouble Codes: Comprehensive List For OBD1/OBD2

DIY Repair Level And Estimated Costs

Taking on the diagnostic and repair process outlined above requires a moderate to advanced level of DIY expertise, especially due to the involvement of high-voltage components. While the step-by-step guide offers clear instructions, working on complex systems like HV battery packs demands careful handling and specialized tools.

If you’re uncertain about any aspect of this procedure, it’s strongly recommended to seek assistance from a qualified mechanic or expert technician to ensure safety and accuracy.

Here’s a general cost overview for potential repair tasks that may arise during the process:

| Repair Task | Estimated Cost Range |

| HVBMS Sensor Replacement | $50 – $150 |

| Individual Cell Replacement | $100 – $300 per cell |

| HV Battery Pack Replacement | $1,500 – $5,000 |

| Component Corrosion Treatment | $20 – $100 |

| Diagnostic Scanner Rental/Service | $50 – $150 |

Please note that these cost ranges are approximate and can vary depending on the vehicle’s make and model, as well as the region you’re in. It’s essential to factor in labor costs if seeking professional assistance. Your safety and the vehicle’s proper functioning are of utmost importance; if unsure, consult an expert to ensure a successful repair outcome.

P0A80 Infographic

Final Thoughts

Once you’ve got the P0A80 code, it’s essential to have a grasp of and find solutions for this error code to ensure your vehicle maintains top-notch performance. By equipping yourself with the right tools and following the step-by-step procedure, you can confidently diagnose and repair hybrid battery issues. Remember, safety comes first, so if in doubt, consult a professional mechanic.

If you found this guide helpful, don’t hesitate to share it with fellow enthusiasts. Have questions or insights? Feel free to comment below – we’re here to help you keep your hybrid running smoothly.

Reference Sources

- OBD-Codes.com, P0A80 Error Code: Replace Hybrid Battery Pack

- National Highway Traffic Safety Administration (NHTSA), Technical Service Bulletin: MC-10131823-9999

- Synopsys, Battery Management System (BMS)

P0050 Code: Understanding Its Causes, Symptoms, and Repairs

P0050 Code: Understanding Its Causes, Symptoms, and Repairs

Hey there, fellow car enthusiasts and DIY mechanics! Have you ever come across the pesky P0050 error code on your car’s dashboard? Don’t panic! We’ve got your back. In this article, we’ll delve into the P0050 trouble code, specifically referring to the HO2S (Heated Oxygen Sensor) Heater Control Circuit related to Bank 2 Sensor 1. If you’ve encountered this code during a diagnostic scan, don’t worry. We’re here to help you understand its meaning, severity, symptoms, causes, necessary diagnosis and repair steps. So, let’s get started!

P0050 Code: Quick Overview

Here is an overview of the P0050 code. Take a look!

Definition: HO2S (Heated Oxygen Sensor) Heater Control Circuit Bank 2 Sensor 1

Severity: Medium

DIY Skill Level: Intermediate

Continue To Drive?: Yes (short-term)

Estimated Repair Cost: $100 – $300

What Does The P0050 Code Mean?

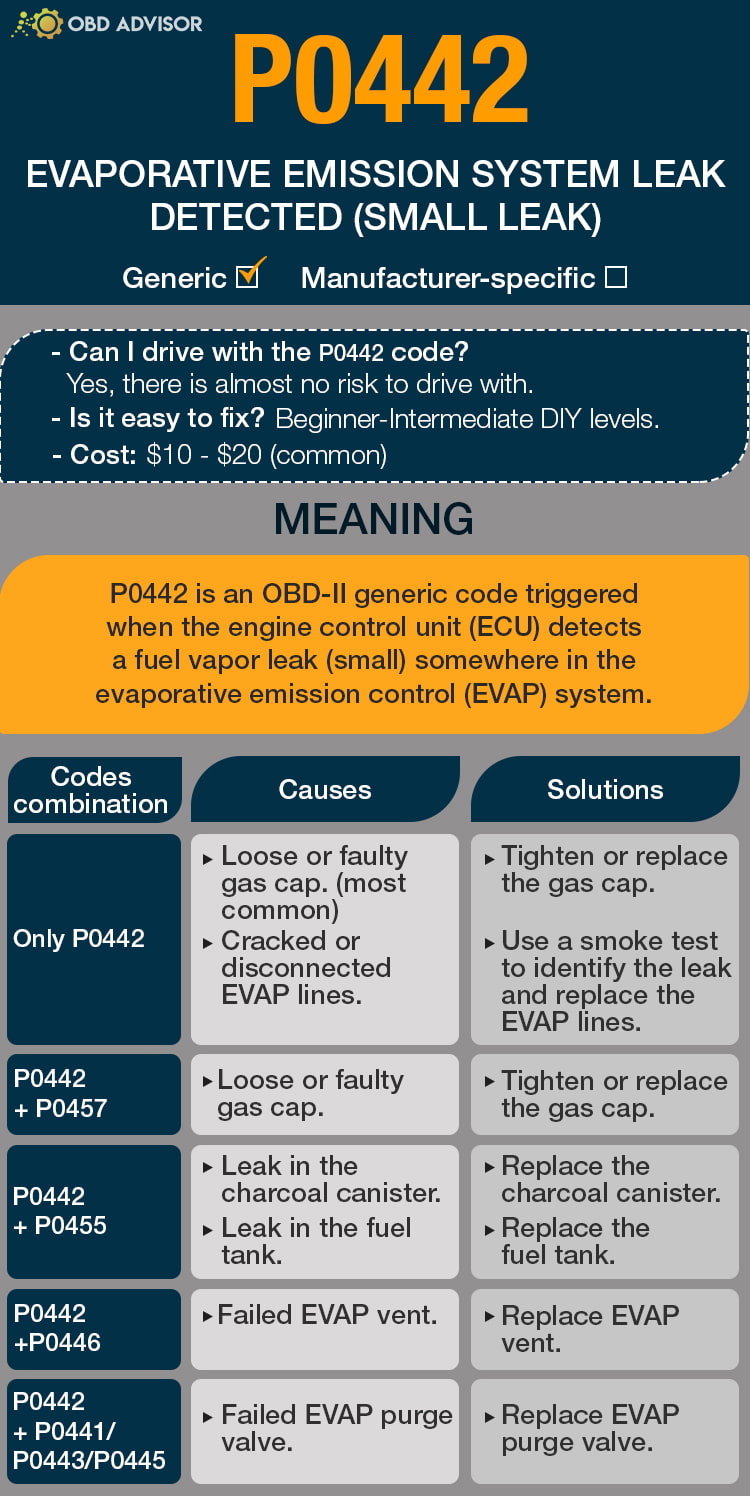

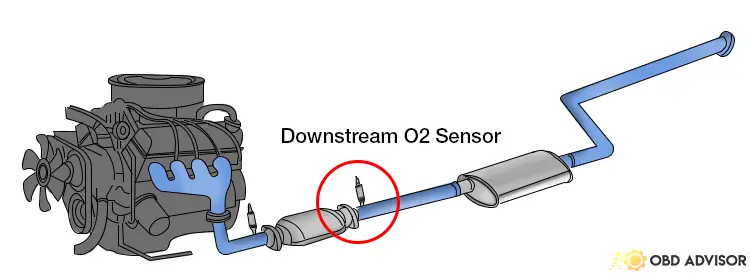

The P0050 code is triggered when the engine control module (ECM) detects an issue with the heater control circuit for Bank 2 Sensor 1. Bank 2 refers to the side of the engine that does not contain cylinder number one, while Sensor 1 denotes the upstream sensor located before the catalytic converter.

In modern vehicles, the engine management system relies on sensors to monitor various parameters and ensure optimal performance. One critical sensor is the oxygen sensor, also known as the HO2 sensor. Its primary function is to measure the oxygen content in the exhaust gases and provide feedback to the ECM for efficient fuel delivery and emissions control.

It’s important to note that the P0050 code is commonly associated with other related trouble codes, such as P0030, P0036, and P0056. These codes all indicate potential problems with the HO2S heater control circuit but may vary regarding the sensor position. Additionally, while the P0050 code can occur in various car brands, it is frequently found in vehicles such as Ford, Chevy (Silverado), BMW, and GMC.

How Severe Is P0050?

When it comes to the severity of the P0050 trouble code, it is considered a moderate issue. While this code doesn’t typically pose an immediate threat to your safety, it should not be ignored either due to its potential impact on fuel efficiency, engine performance, and emissions control.

It’s important not to drive for too long without fixing the P0050 code. While your vehicle may still operate, it’s important to address the underlying problem promptly to prevent potential long-term damage and ensure optimal engine performance. Taking proactive steps to resolve the P0050 code will help maintain your vehicle’s efficiency, performance, and overall reliability.

Read more: P0135 – O2 Sensor Heater Circuit Malfunction (Bank 1, Sensor 1)

Common Symptoms of P0050

The P0050 trouble code can cause various symptoms, including:

- Check Engine Light (MIL) illuminated

- Decreased fuel efficiency

- Rough idle or engine misfires

- Engine hesitation or stalling

- Failed emissions test

- Decreased engine performance

Causes of the P0050 Code

Several underlying causes can trigger the P0050 trouble code, including:

- Faulty HO2S heater control circuit

- Damaged or malfunctioning oxygen sensor

- Wiring or connector issues in the heater circuit

- Blown fuse related to the sensor heater

- Faulty ECM

Read more: P0161 – O2 Sensor Heater Circuit

How To Diagnosis And Fix The P0050 Code

When it comes to diagnosing and repairing the P0050 trouble code, it is essential to have the right tools and follow a systematic procedure. Let’s explore the necessary tools and parts, along with a step-by-step guide to resolving the code.

Essential Tools and Parts

- OBD-II scanner

- Digital multimeter

- Oxygen sensor socket

- Wire crimping tool

- Electrical contact cleaner

- Replacement oxygen sensor (if necessary)

- A test light

- Electrical connectors and wiring

Step-by-Step Procedure

Step 1: Retrieve the trouble codes and record freeze frame data

Use an OBD-II scanner to retrieve P0050 and any associated code. Take note of any freeze frame data, which provides additional information about the conditions when the code was triggered.

Step 2: Inspect the oxygen sensor wiring and connectors

Thoroughly examine the wiring and connectors associated with the affected oxygen sensor. Look for signs of damage, corrosion, or loose connections. Repair/clean if needed.

Step 3: Test the oxygen sensor heater circuit

Use a digital multimeter to check the resistance and voltage of the oxygen sensor heater circuit and compare it to the manufacturer’s specifications. If the reading is out of range, repair the circuit.

Step 4: Check the fuse related to the sensor heater

Locate the fuse responsible for the oxygen sensor heater circuit and inspect it for any signs of damage or blown fuse. Replace the fuse if necessary, ensuring it matches the proper specifications.

Step 5: Replace the oxygen sensor

Use a multimeter to test the oxygen sensor’s voltage. If the voltage is outside the range in the vehicle’s repair manual, it indicates it’s faulty. Replace the sensor following the manufacturer’s guidelines for proper installation and ensure the new sensor is compatible with your vehicle.

Step 6: Clear the codes and perform a road test

Once the repairs have been made, clear the trouble codes using an OBD-II scanner. Take the vehicle for a road test to ensure the P0050 code does not reappear and that the engine is running smoothly.

Notes:

- It’s recommended to consult the vehicle’s service manual for detailed instructions specific to your make and model.

- If you are unsure or uncomfortable with the diagnostic and repair procedures, it is best to seek assistance from a qualified mechanic.

DIY Repair Level and Estimated Costs

The diagnosis and repair of the P0050 code fall under intermediate-level repairs that require some technical knowledge. If you’re confident in your abilities, you can attempt the procedure. However, if you’re unsure or uncomfortable, it’s best to seek assistance from a professional mechanic.

Here’s a breakdown of the estimated costs for common repair tasks:

| Repair Task | Estimated Cost Range |

| Oxygen sensor replacement | $100 – $300 |

| Wiring or connector repair | $100 – $200 |

| Fuse replacement | $10 – $20 |

| Professional diagnostics | $80 – $150 (approx.) |

Please note that these approximate cost ranges can vary depending on the vehicle’s make and model, labor rates in your area, and the specific cause of the P0050 code. It’s always a good idea to consult a professional mechanic who can provide a more accurate estimate based on your circumstances.

Final Thoughts

Understanding the P0050 trouble code and its meaning can empower you to take the necessary knowledge for diagnosis and repair. By recognizing this code’s symptoms, causes, and severity, you can make informed decisions to maintain your vehicle’s performance and reliability.

Remember, if you’re confident in your DIY skills, you can attempt the repair procedure mentioned in this article. However, if you’re unsure or prefer the expertise of a professional, don’t hesitate to seek assistance from a qualified mechanic.

We hope this guide has shed light on the P0050 trouble code and provided valuable insights into its meaning and repair. If you found this article helpful, feel free to share it with others who may benefit. And if you have any questions or experiences to share, don’t hesitate to leave a comment below.

Safe travels and happy motoring!

Reference:

Freeasestudyguides. com – Heated Oxygen Sensors

P2118 Code: A Guide to Throttle Actuator Control Motor Issues

P2118 Code: A Guide to Throttle Actuator Control Motor Issues

Welcome to our comprehensive guide on the P2118 engine code, a common issue related to throttle actuator control motors.

If you’ve encountered this code, you’re not alone. In this article, we’ll explore the meaning, severity, symptoms, causes, and diagnostic process for P2118. We aim to equip you with the knowledge to understand this code and its implications for your vehicle’s performance.

So, let’s dive in!

P2118 Code: A Quick Overview

Here is an overview of the P2118 code. Let’s take a look!

- Definition: Throttle Actuator Control Motor Current Range/Performance

- Severity: High

- DIY Skill Level: Intermediate

- Continue To Drive?: No

- Estimated Repair Cost: $100 – $500

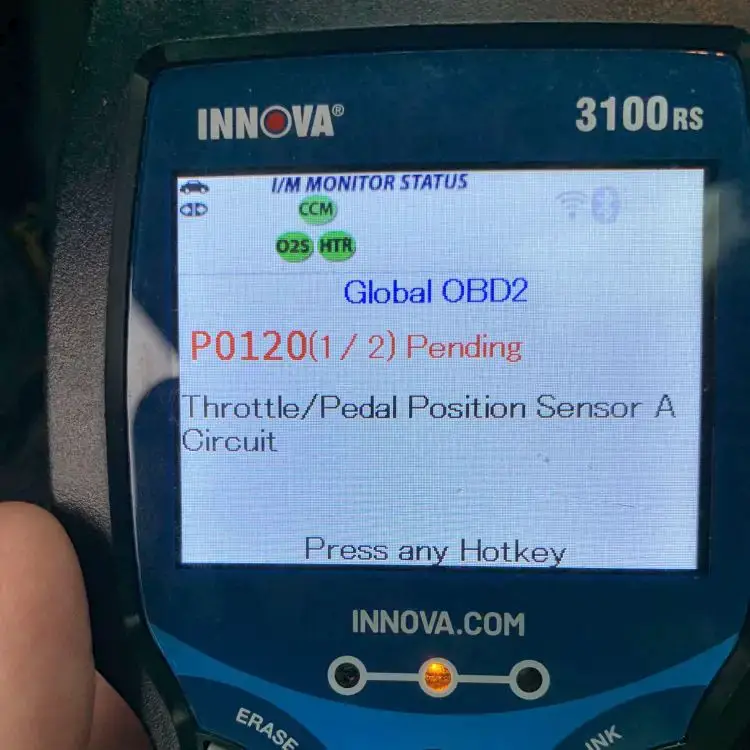

What Does The P2118 Mean?

The P2118 engine code indicates a malfunction in the operation of the Throttle Actuator Control System. This system is responsible for regulating the airflow into the engine by controlling the position of the throttle plate.

When the Powertrain Control Module (PCM) detects an issue with this system, such as voltage readings or performance outside the expected range, it triggers the P2118 code. This serves as a warning that there may be a problem with the current range and performance of the throttle actuator control motor.

It’s worth noting that the P2118 code is commonly found in various car brands, including Toyota, Lexus, Ford, KIA, and Hyundai. Additionally, it is often associated with codes P2102, P2103, P2107, P2108, P2110, P2111, and P2119, which relate to the throttle actuator control system.

Read more: P0122 – Throttle/Pedal Position Sensor/Switch “A” Circuit Low

Can You Still Drive With The Code P2118?

The P2118 engine code is considered a high severity level. This code directly affects the engine’s performance and drivability, so it should not be overlooked.

Driving with the P2118 code present can result in severe consequences. The engine may experience reduced power, poor acceleration, and potentially even stalling. These issues can compromise the safety of both the driver and the vehicle.

So, it is strongly advised not to continue driving with the P2118 code unresolved. Instead, it is essential to diagnose and repair the underlying problem as soon as possible. Promptly addressing this code will restore optimal throttle actuator control system function, ensuring the safe and efficient operation of your vehicle.

Signs Of The P2118 Code

Here are some common symptoms typically seen with this code:

- Illuminated check engine light, TRAC OFF light

- Limp mode (Fail-safe mode)

- Reduced engine power or lack of acceleration

- Engine stalling or rough idle

- Hard starting

- Little or no throttle response

Causes Of The P2118 Code

Here are some possible triggers:

- Faulty throttle actuator control motor

- Issues with the throttle body or throttle position sensor

- Defective accelerator pedal position sensor

- Wiring or electrical connection problems

- Blown throttle actuator control motor’s fuse

- Malfunctioning PCM

How Do I Diagnose And Fix The P2118 Code?

In this section, we will explore the essential tools and parts required for diagnosing and repairing the P2118 code, provide a step-by-step procedure to address the issue and discuss the level of DIY repair along with estimated costs.

Essential Tools and Parts

- OBD-II scanner

- Multimeter

- Throttle actuator control motor replacement (if necessary)

- Throttle body cleaner

- Electrical contact cleaner

- Wire connectors and electrical tape

Step-by-Step Procedure

- Retrieve the trouble codes using an OBD-II scanner.

- Check the throttle actuator control motor’s fuse on the junction box with a test light. Replace the fuse if it doesn’t work properly.

- Inspect the throttle body and wiring connections for any signs of damage or loose connections. Clean/repair it if needed.

- Check other components related to the Throttle Actuator Control System, such as the throttle position sensor and accelerator pedal position sensor, to ensure it works properly. Replace any faulty components if it’s bad.

- Test the throttle actuator control motor’s voltage using a multimeter. If the voltage is outside the range in the vehicle’s repair manual, replace it with a new one.

- Inspect the electrical wiring and connections associated with the throttle actuator control system. Clean/replace it if you see any dirt or damage.

- Clear codes and test drive to ensure the issue has been resolved.

Note:

- It is recommended to consult the vehicle’s repair manual for detailed instructions specific to your make and model.

- Double-check all before reassembling.

DIY Repair Level And Estimated Costs

Regarding the P2118 code, tasks like cleaning the throttle body and changing the car fuse are within the capabilities of most DIY enthusiasts. However, replacing the throttle actuator control motor may require advanced knowledge and specialized tools, making it better suited for individuals with intermediate to advanced DIY skills.

Here’s a breakdown of estimated costs for the main repair tasks to repair the P2118 code:

| Repair Task | Estimated Cost |

| Wiring Repairs | $50 – $150 |

| Blown Fuse Replacement | $50 – $100 |

| Throttle Body Cleaning | $10 – $30 |

| Throttle Actuator Control Motor Replacement | $150 – $500 |

Please note that these estimated costs are approximate and can vary depending on the vehicle’s make, model, and location. Additionally, prices for parts and labor can vary among different service providers. It’s always recommended to obtain quotes from reputable mechanics or parts suppliers for a more accurate estimate based on your specific circumstances.

Final Thoughts

In conclusion, the P2118 engine code indicates a significant issue with the throttle actuator control motor’s current range and performance. Ignoring this code can lead to reduced engine power, stalling, and compromised driving safety. Prompt action is crucial.

If you’re experiencing the symptoms associated with the P2118 code, it’s essential to diagnose and address the underlying problem. While DIY enthusiasts can tackle some tasks, assistance from a qualified mechanic is advisable for complex repairs.

We hope this guide has provided valuable insights into the P2118 code. If you found it helpful, feel free to share it with others. If you have any questions or comments, please leave them below.

Safe and smooth driving!

Reference:

- Wikipedia – Electronic throttle control

- Toyota – T-TT-0321-15 TSB

- Toyota 20RAV4 – Repair Manual

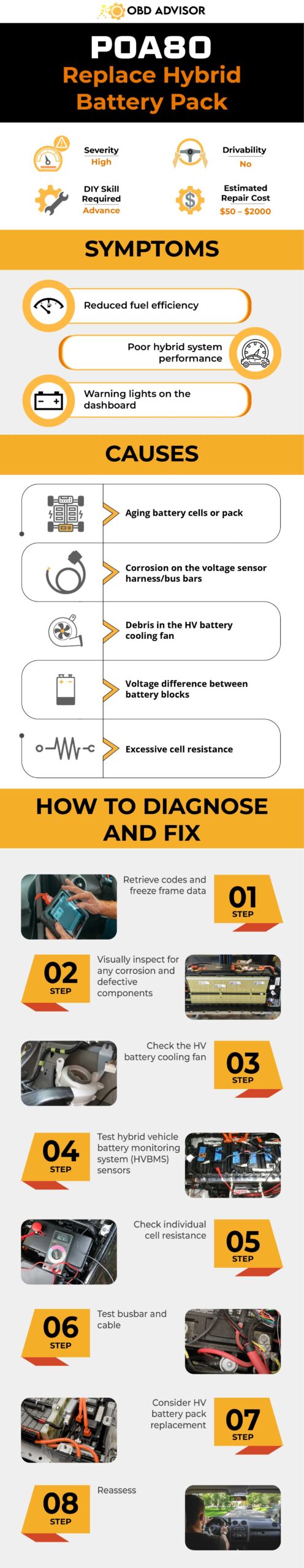

P00B7 Code: Ensuring Proper Engine Coolant Flow

P00B7 Code: Ensuring Proper Engine Coolant Flow

When that check engine light suddenly appears on your dashboard and the P00B7 code pops up on your scanner’s screen, your vehicle is sending a signal about a potential hiccup in its cooling system. In this article, we’re here to break down the meaning behind this code, highlight possible indicators, explain why it occurs, and provide step-by-step guidance to diagnose and resolve the issue.

Whether you’re a seasoned car enthusiast or simply curious about what’s happening beneath the hood, this article will simplify the process of dealing with the P00B7 code.

Let’s dive in!

P00B7 Code: A Quick Overview

- Definition: Engine Coolant Flow Low/Performance

- Severity: Medium

- DIY Skill Level: Intermediate

- Continue To Drive?: No

- Estimated Repair Cost: $50 – $500

What Does the P00B7 Code Mean?

When your car’s computer (PCM) detects code P00B7 – Engine Coolant Flow Low/Performance, it’s essentially saying that there’s a problem with how coolant is flowing through your engine’s cooling system. In simpler terms, your engine might not be getting enough coolant to stay cool.

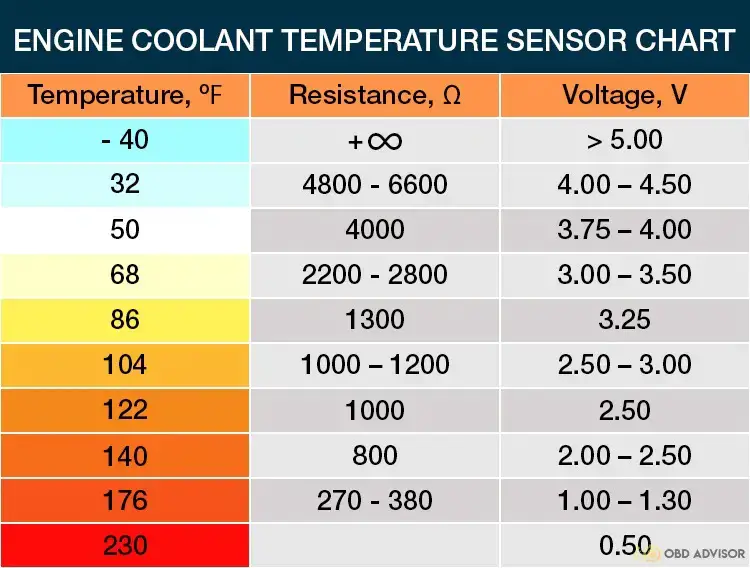

This code shows up when the PCM notices a mismatch between signals from two temperature sensors: the engine coolant temperature (ECT) sensor and the radiator coolant temperature (RCT) sensor (or secondary engine coolant temperature sensor). This mismatch usually occurs when the PCM can’t control the thermostat properly. Think of it like the PCM trying to balance the engine’s temperature by using these sensors, and when they don’t agree, it suspects there’s a coolant flow issue.

Your car’s PCM keeps a close eye on both sensors. If it sees a significant temperature difference (more than 68°F) between the radiator coolant temperature sensor (RCT) and the engine coolant temperature sensor (ECT), the P00B7 would be logged.

To prevent the engine from getting too hot, the PCM might kick the radiator fan(s) into high gear. This mechanism helps cool things down and prevents overheating. Code P00B7 can be encountered in various vehicle brands and models, including Chevrolet, GMC, Buick, Cadillac, and other manufacturers.

How Serious is the P00B7 Code?

The severity of code P00B7 falls into the moderate category. While it doesn’t represent an immediate danger like some other codes, it does require attention. Continuing to drive with this code present is generally not recommended. A restricted coolant flow can lead to overheating, which, if left unchecked, may cause engine damage. Overheating can also compromise your vehicle’s performance and fuel efficiency.

It’s advisable to address code P00B7 promptly. Have your vehicle inspected by a qualified mechanic to determine the exact cause. Timely maintenance can prevent more extensive and costly issues down the road, ensuring your vehicle operates efficiently and reliably.

What are the Symptoms of the P00B7 Code?

Here are some common symptoms that come along with the P00B7 code:

- Illuminated Check Engine Light

- Engine running rough

- Poor fuel economy

- Engine overheating

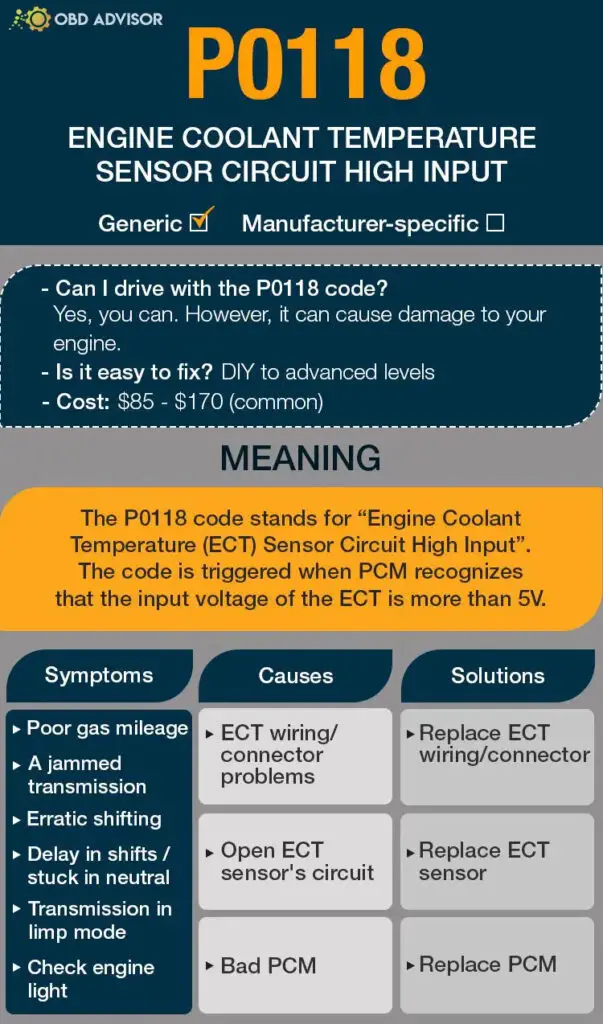

Read more: P0118: Engine Coolant Temperature Sensor Circuit High Input

What are the Causes of the P00B7 Code?

Now, let’s go through the potential causes of the P00B7 code:

- Wiring or connector problems in the thermostat circuit

- Low coolant level

- Bad water pump

- Damaged thermostats

- Malfunctioning ECT sensor

- Defective RCT sensor

- Faulty PCM/ECM

How To Diagnose and Repair P00B7 Code?

Diagnostic Tools and Essential Parts

When dealing with the P00B7 code, having the right tools and parts on hand is crucial. Here’s what you’ll need:

- OBD-II scanner

- Multimeter

- Coolant

- Thermostat replacement kit

- Wiring repair kit

- ECT sensor

- RCT sensor

Step-by-Step Guide

- OBD-II Code Retrieval:

Begin by using an OBD-II scanner to confirm the P00B7 code and assess any accompanying codes. - Wiring and connectors checking:

Inspect the PCM/ECM power relay for signs of damage or wear. If it’s faulty, replace it.

- Coolant level inspection:

Verify the coolant level is adequate. Top it up if it’s low.

- ECT and RCT Testing:

- Make sure the car’s ignition is off and unplug the sensors.

- Using a multimeter to check the resistance of each sensor.

- Compare the results to your car’s repair manual specs.

- If it’s not within the range, consider replacing the sensors.

- Checking the Thermostat

- Locate the thermostat housing on your vehicle’s engine.

- Remove the thermostat and inspect it for any signs of wear, such as rust or corrosion.

- Replace the thermostat if it shows signs of damage.

- PCM/ECM Testing (if needed):

- If the issue persists after addressing the above steps, consult a professional mechanic or auto technician to perform a diagnostic check on the PCM/ECM.

- They will use specialized tools to diagnose and potentially reprogram the PCM/ECM, if required.

- Clearing the code:

Clear the code and test drive.

Special Notes

If you have a Chevrolet or Cadillac vehicle, please check for this Technical Service Bulletin (TSB) (PIE0266) to see if they include your model or not. Similarly, Vauxhall Meriva (2011-2012) owners should look for this TSB. These TSBs often contain valuable information regarding known issues and solutions.

Keep in mind that the exact procedure may vary depending on the type of sensors and thermostats in your specific vehicle model, so it’s essential to consult your vehicle’s repair manual for precise testing instructions and specifications.

Read more: P0128 – Coolant thermostat

DIY Repair Level and Estimated Costs

This repair falls into the intermediate DIY category. While some experienced home mechanics may tackle it, others may prefer consulting a professional, especially when dealing with the PCM/ECM.

Take a look at this rough estimate for P00B7 solutions:

| Repair Task | Estimated Cost |

| Wiring and connector repair | $50 – $150 |

| ECT sensor replacement | $200 – $400 |

| RCT sensor replacement | $200 – $400 |

| Water pump replacement | $400 – $600 |

| Thermostat replacement | $150 -$300 |

| PCM/ECM replacement (rarely) | $500 – $1500 |

Please note that the estimated costs provided are approximate. For precise repair costs, we recommend consulting a certified mechanic or dealership. They can provide an accurate quote based on your vehicle’s make, model, and the extent of the required repairs.

Conclusion

Now that you have a clearer understanding of code P00B7 and its implications for your vehicle’s cooling system, you’re better prepared to address this issue confidently. By taking prompt action, you can ensure your engine stays within the suitable temperature range, keeping your car running smoothly.

If you found this article helpful, consider sharing it with other car owners who drive different makes and models, as the P00B7 isn’t exclusive to any particular brand.

Have you ever encountered the P00B7 code, or do you have additional insights or tips to share with the community? Feel free to drop a comment below. Your experiences and advice can be invaluable to others facing similar automotive issues.

Reference Sources

TechTips, Opel Meriva B – Fault Code P00B7.

P015B Code: Understanding Oxygen Sensor Issues

P015B Code: Understanding Oxygen Sensor Issues

Your vehicle suddenly experienced issues; you connected a diagnostic tool and discovered the P015B code. What happened to your car?

Well, P015B specifically refers to a delayed response from the Oxygen sensor (O2 sensor) in Bank 1, Sensor 1, resulting in a transition from a rich to a lean air-fuel mixture. This can have an impact on the vehicle’s performance and fuel efficiency.

Keep reading if you’re curious to learn more about the P015B code, its implications, and how to address it. We’ll guide you through the process, providing expert insights and practical solutions to help you get your vehicle back on track.

Let’s dive in!

P015B Code: Quick Overview

Here’s a glance at the key details regarding the P015B code!

- Definition: O2 sensor Delayed Response – Lean to Rich (Bank 1, Sensor 1)

- Severity: Medium

- DIY Skill Level: Intermediate

- Continue To Drive?: No

- Estimated Repair Cost: $50 – $300

What Does the P015B Code Mean?

The P015B code indicates a specific issue with the O2 sensor in Bank 1, Sensor 1, of the vehicle’s exhaust system. This sensor is responsible for measuring the oxygen content in the exhaust gases and providing feedback to the engine control module (ECM) to ensure optimal air-fuel mixture for combustion.

The code is commonly triggered in various car models, including Chevy (especially Cruze, Silverado, Tahoe, and Malibu), GMC, Nissan, Subaru, and Buick. However, it’s important to note that the P015B code can also be present in other vehicles as it’s a generic OBD-II code.

To understand why the P015B code is triggered, let’s take a closer look at the systems and components involved. In modern vehicles, the exhaust system consists of multiple O2 sensors strategically placed before and after the catalytic converter. The O2 sensor in Bank 1, Sensor 1, is located on the side of the engine where cylinder 1 is present.

The O2 sensor works with the ECM and other engine sensors to maintain the proper air-fuel ratio. It continuously measures the oxygen content in the exhaust gases before they enter the catalytic converter. Based on this measurement, the ECM adjusts the fuel delivery to ensure efficient combustion. When the O2 sensor in Bank 1, Sensor 1, experiences a delayed response in transitioning from a rich (more fuel) to a lean (less fuel) air-fuel mixture, it triggers the P015B code.

Read more: P0151 Code: Understanding O2 Sensor Circuit Low Voltage

How Serious is the P015B Code?

The P015B code could affect the engine’s air-fuel mixture and, consequently, its performance and fuel efficiency. Therefore, this diagnostic trouble code (DTC) should be considered a medium-to-high severity.

While the P015B code itself may not cause immediate or severe damage to the vehicle, it’s important not to ignore it. Continuously driving with the code unresolved can lead to long-term issues, such as reduced fuel economy, engine misfires, or damage to the catalytic converter.

Therefore, we strongly advise against continuing to drive and ignoring the P015B code. It’s best to address the underlying cause promptly to prevent any potential complications. By diagnosing and repairing the issue, you can restore the proper functioning of the O2 sensor and ensure optimal engine performance.

Read more: P0171: System Too Lean (Bank 1)

Signs of the P015B Code

When your vehicle encounters the P015B code, it may exhibit certain symptoms that indicate the presence of this issue.

- Illuminated Check Engine Light (CEL) or Service Engine Soon (SES) Light

- Poor fuel economy

- Reduced engine performance

- Increased emissions

- Rough idling and engine misfiring (less common)

Read more: P0172: System Too Rich (Bank 1)

Potential Triggers of the P015B Code

The P015B code can be triggered by various underlying causes.

- Malfunctioning O2 sensor

- Wiring or connector issues

- Exhaust leaks

- Fuel system problems

- Faulty ECM

How To Effectively Diagnose and Fix The Code P015B?

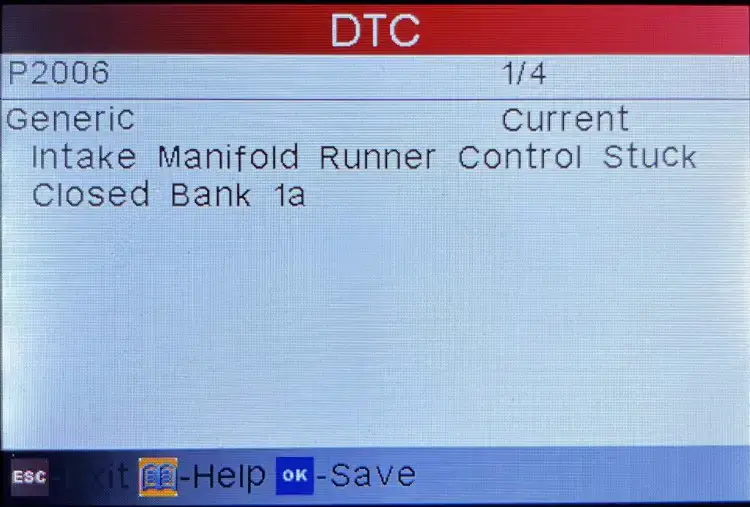

Take a look at this section, which provides step-by-step instructions for diagnosing and repairing the P2006 code.

Essential Tools and Parts

To diagnose and repair the P015B code, you will need the following tools and parts:

- OBD-II scanner or code reader

- Multimeter

- Oxygen sensor socket or wrench

- Wire crimping tool

- Replacement O2 sensor (if necessary)

Step-by-step procedure

Step 1: Use the OBD-II scanner or code reader to retrieve the P015B and any accompanying codes.

Step 2: Inspect the wiring and connectors associated with the O2 sensor. Look for any visible damage, corrosion, or loose connections. Repair/ replace any damaged components as necessary.

Step 3: Test the O2 sensor using a multimeter to measure its voltage output and response time. If the O2 sensor fails the tests, it may need to be replaced. Refer to the vehicle’s manual or online resources for the specific replacement procedure.

Step 4: Inspect the exhaust system for any leaks or damage. Check for signs of leakage, such as sooty deposits or unusual noises. Repair any identified exhaust leaks promptly.

Step 5: Examine the fuel system components, including the fuel injectors, fuel pressure regulator, and fuel lines, for any issues. Look for clogs, leaks, or improper fuel pressure. Address any fuel system problems found during the inspection.

Step 6: Clear the codes using the OBD-II scanner or code reader. This will reset the vehicle’s ECM. Perform a test drive to monitor the vehicle’s performance and confirm if the issue has been resolved.

Notes and tips:

- The location of the O2 sensor may vary depending on the car model. For example, in a Chevy Cruze, the Bank 1 Sensor 1 is located in the exhaust manifold, while in a Nissan Altima, it is found in the front exhaust pipe.

- If the code still exists, after all, the ECM may be faulty. However, diagnosing and fixing ECM issues usually requires special tools and expertise. Consult a professional mechanic or authorized service center for further diagnosis and ECM-related repairs if needed.

DIY Repair Level and Estimated Costs

The diagnosis and repair of the P015B code can be considered a moderate-level DIY repair. It requires some technical knowledge and the use of specialized tools. If you’re unsure or uncomfortable performing the tasks, you should seek assistance from an expert or a qualified mechanic.

The estimated cost for the repair tasks associated with the P015B code can vary depending on factors such as the vehicle model, the need for parts replacement, and the labor rates in your area. Here is a breakdown of estimated costs for common repair tasks associated with addressing the P015B code.

| Repair Task | Estimated Cost |

| Wiring or connector repair/replacement | $50 – $200 |

| Replacement O2 sensor | $50 – $200 |

| Exhaust system repair | $200 – $1000 |

| Fuel system repair | $150 – $800 |

It’s essential to consult with a mechanic or obtain accurate cost estimates from local repair shops to better understand the specific costs involved in resolving the P015B code for your particular vehicle.

Wrapping Up

Now that you understand the P015B code and its significance in your vehicle, you’re ready to tackle this frustrating issue confidently. We hope our comprehensive guide has empowered you to effectively address the code and its causes. With this knowledge, you can approach the P015B code with confidence, knowing you have the tools to deal with it.

If you found this article helpful, please share it with fellow car enthusiasts and leave a comment below to share your experience or ask questions. For a complete list of OBD codes, use our user-friendly OBD Code list generator or try our OBD code lookup tool for specific DTCs.

Stay proactive for smoother driving!

Reference Sources

Wikipedia, Air-fuel ratio.

Autoscope, What Are The Differences Between Lean And Rich Mixtures In An Internal Combustion Engine?.

P0325 – Knock sensor 1 circuit

P0325 – Knock sensor 1 circuit

The P0325 code relates to the knock sensor on the bank 1 side of your car’s engine. It basically tells you it isn’t sending the right signals to the computer. There are a lot of reasons this could be happening, from bad wiring to a faulty sensor.

P0325 is a generic powertrain code that applies to a wide range of vehicle types. Having said that, it’s seen more often on certain cars than others. It’s more common in Asian cars than those made in the United States or Europe and is most common on Hondas, Nissans, and Toyotas.

You won’t likely experience any drivability issues when the P0325 code is active, but that doesn’t mean you can ignore it. Read on below to learn how to diagnose and repair this knock sensor trouble code before it leads to further problems.

P0325 code definition

P0325 code definition (generic): Knock sensor circuit malfunction (bank 1)

P0325 Honda code definition: Knock sensor circuit malfunction

P0325 Hyundai code definition: Knock sensor circuit malfunction

P0325 Nissan code definition: Knock sensor circuit malfunction

P0325 Toyota code definition: Knock sensor circuit malfunction

What does P0325 mean?

The knock sensor in your engine is there to tell you when the air/fuel mixture isn’t combusting properly. It detects explosions, which are called knocks, because of the noise they cause. When knocks happen, the engine doesn’t get as much power. If these happen for too long, it can cause engine damage.

The information sent to the computer from the knock sensor allows it to make adjustments. It may change the timing or otherwise tune the engine to prevent the knocks. You’ll find the knock sensor bolted or threaded into the engine block.

When the engine computer isn’t receiving the right information from the knock sensor, it triggers the P0325 trouble code. This code specifically refers to the knock sensor on bank 1 of the engine. Bank 1 is the side that includes cylinder 1.

What are the symptoms of the P0325 code?

There are not typically any drivability symptoms with the P0325 trouble code. The most common symptoms are:

- Activation of the check engine light

- Reduced engine power

If there are engine knocks occurring as well as damage to the knock sensor, you may notice the following symptoms:

- Hesitation from the engine

- Audible pinging from the engine, especially while accelerating

- Reduced fuel economy

What are the causes of P0325?

- Faulty knock sensor,

- Shorted or faulty wiring in the knock sensor circuit,

- Shorts or faults in the wiring harness,

- Faulty or loose electrical connections,

- Faults with engine coolant system,

- Engine running too lean,

- Failed PCM or ECU.

How serious is the P0325 code?

The P0325 trouble code is of relatively low severity. You won’t notice any drivability symptoms in most cases and can drive your car safely until you can repair it. However, it would be best if you fixed it quickly so you can be notified of knocking problems, which can damage your engine.

How to diagnose the P0325 code

Tools you’ll need:

Method:

- Check your vehicle’s manual for any specific troubleshooting tips related to the knock sensor. You can also check if there are any technical service bulletins out related to this trouble code. The repair for P0325 is often vehicle-specific. Follow any manufacturer-specific instructions you find before proceeding with the generic diagnostic below.

- Use your OBD2 scanner to check for any other codes. You may see other codes related to the knock sensor, such as P0330. If you see codes related to other sensors, such as the MAF sensor or oxygen sensors, this likely points to a wiring problem.

- Read the freeze frame data related to the knock sensor. Check the conditions that were present when the code was set, which can help you make a complete diagnosis.

- Clear the codes and test drive your vehicle, attempting to replicate the conditions of the failure.

- Verify that the knock sensor is sending a signal to the powertrain control module. If it’s not, use the OBD2 scanner to check the readings from the coolant temperature sensor.

- Visually inspect the wires around the knock sensor and wiring harness. Replace any wires that are damaged or corroded and ensure all the connections are secure.

Common mistakes to avoid while diagnosing the P0325 code

Many people replace the knock sensor before checking the wiring or looking for issues with the coolant system. Make sure you conduct a thorough diagnosis before replacing any components.

What should you do to fix the code P0325?

After each step of your repairs, clear all the trouble codes and test drive your vehicle to see if the code comes back. Since there are rarely drivability issues with this code, your OBD2 scanner will be crucial in discovering if you’ve fixed the problem.

- Replace any damaged wires you found during your diagnosis.

- If you detected any issues with the coolant temperature readings, replace the temperature sensor. Incorrect temperature readings can lead to overheating and other serious engine issues.

- If you’re certain there are no damaged wires or missing connections in your engine, replace the knock sensor and the knock harness.

- Should the P0325 code still not clear, take your car to a mechanic for further diagnosis. In rare instances, this code could indicate a problem with your electrical connections or the engine computer.

Tips to avoid P0325 in the future

An improperly-installed knock sensor is the most common cause of a P0325 code. Wires that aren’t firmly connected could be shaken loose over time by the vibration of the engine. Damaged or broken wires will also often trigger diagnostic trouble codes—not only P0325 but a host of codes related to sensors throughout your engine.

Take the extra time to check all the wires whenever you install or repair something in your engine. Check that the connections are secure and that the wires are clear of things that could cause damage or shorts.

Read more: P0010 Code: Meaning, Symptoms, Causes, Diagnostics, and Fixes

C0035 Code: Understanding Wheel Speed Sensor Issues

C0035 Code: Understanding Wheel Speed Sensor Issues

Encountering the C0035 code? Don’t worry – we’re here to help. The C0035 code is a common ABS fault code that relates to wheel speed sensor issues in vehicles.

In this comprehensive article, we’ll be your trusted companion as we explore the ins and outs of the C0035 code. From identifying symptoms to uncovering causes and offering practical solutions, we’ve got you covered.

So, let’s dive in!

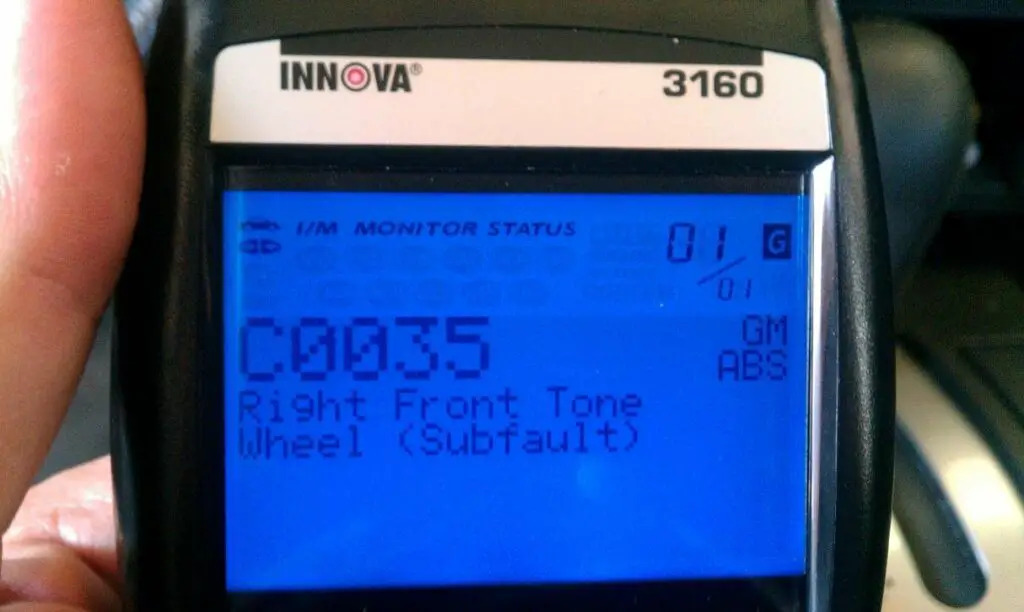

C0035 OBD2 Code: A Quick Overview

Take a quick look at the key information of the C0035 code below!

- Definition: Right Front Wheel Speed Sensor Supply (subfault)/ Left Front Wheel Speed Sensor

- Severity: High

- DIY Skill Level: Intermediate

- Continue To Drive?: No

- Estimated Repair Cost: $30 – $200

What Does The C0035 Code Indicate?

The C0035 code indicates a fault related to the wheel speed sensor in the vehicle’s anti-lock brake system (ABS). Although this is a generic fault code, which can happen on all cars equipped with the OBD2 system, it most frequently occurs in GM vehicles, including popular models like Chevy Silverado, Impala, and Equinox.

The wheel speed sensors play a vital role in the ABS system. Each wheel speed sensor generates a digital square wave signal as the front wheels spin. The electronic brake control module (EBCM) relies on the frequency of these signals to determine the speed of each wheel. When the EBCM detects an issue with the front wheel speed sensor or its circuit, such as a missing signal or significantly low supply voltage compared to the monitored ignition voltage, it logs the C0035 code.

Special Note:

There might be variations in code definitions depending on the car model. When researching information about the C0035 code, you might come across these two definitions: “Right Front Wheel Speed Sensor Supply (subfault)” and “Left Front Wheel Speed Sensor.”

In certain GM vehicles, the code is commonly referred to as “Right Front Wheel Speed Sensor Supply (subfault). The SAE organization also uses this definition for the C0035 code. While most cars will display the code in reference to the right front wheel, there are a few exceptions where it may pertain to the left wheel instead.

To accurately diagnose the problem in your specific vehicle, it’s crucial to not only consider the diagnostic code you receive but also carefully review the short description of the problem that your car is experiencing.

C0035 Severity: Don’t Ignore It!