Symptoms like bad fuel economy, poor drivability, and transmission shifting problems can be attributed to a bad camshaft position sensor. A faulty camshaft position sensor will set you back $95 to $200 for replacing the parts and labor costs for professional replacement.

The electronic device is critical in helping the PCM (Powertrain control module) to determine the amount of fuel going into the combustion chamber. In this article, we will dive into the purpose of the camshaft position sensor, symptoms of a bad one, causes, and other related questions regarding the sensor.

What does a camshaft sensor do?

The camshaft position sensor is placed close to the cylinder head for it to be mounted opposite to the timing rotor. The camshaft position sensor is mounted in this manner to ensure it can detect the rotation of the camshaft; camshaft speed and position.

The information (camshaft speed and position) is sent to the Powertrain Control Module or Engine Control Module (ECM). The PCM will then proceed to use this information to determine how much fuel can be allowed into the cylinders. The PCM will also use this information to ensure the timing rotor is well adjusted to ignite the air and fuel mixture at the most opportune time.

The crankshaft sensor is used in combination with the camshaft position sensor to help determine the precise position of the crankshaft drive. These two sensors will use their signals to tell the PCM when the first cylinder is at the top dead point.

The ECM will then use the crankshaft and camshaft sensor information to start fuel injection during the sequential injection. Additionally, the ECM will use the sensors’ data for cylinder-selective knocking control and actuate the signal of the solenoid valve for the pump-nozzle injection system.

The camshaft position sensor is therefore a critical component that ensures your car has the best engine power and better fuel economy. Moreover, the camshaft position sensor helps reduce the number of emissions that come out of the tailpipe.

Symptoms of a bad camshaft position sensor

An illuminated check engine light

The onboard diagnostic system (OBD) is efficient at detecting hardware and software changes which include a malfunctioning sensor such as the camshaft position sensor. A bad camshaft position sensor will cause performance fluctuations that will be easily detected by the OBD system. The OBD system will then illuminate the check engine light to show you there is a problem that needs your immediate attention.

There are several other causes for an illuminated check engine light. Make sure to equip yourself with an OBD2 scan tool to be able to identify the specific stored codes in the system that may indicate a bad camshaft position sensor. You will have to take to a professional mechanic who can be able to accurately identify the issue in case you are not experienced in using the scan tool.

A generic OBD2 diagnostic trouble code like P0340 will be stored by the PCM to indicate ‘Camshaft Position Sensor “A” circuit malfunction. The P0340 code relates to a problem located somewhere in the entire camshaft position sensor circuit including wiring and the sensor itself. Different car manufacturers will have various specific codes that will help pinpoint the issue more precisely.

FOXWELL NT301 OBD2 Scan Tool

Bluedriver Bluetooth OBD2 Scanner

Bonus: Find your best scanner with the Quick Search Tool on https://obdadvisor.com/

Starting difficulties and general poor drivability

Difficulties starting your vehicle will begin once the camshaft sensor has deteriorated for quite some time. You will typically not expect this in the early stages of a camshaft sensor malfunction. As the sensor becomes worse, so does the signal that is emitted from the sensor to the PCM.

The result of this is a weak signal that will eventually stop transmitting causing the engine and the PCM to fail to perform their respective timing tasks. You may experience this problem when the vehicle is parked or when you are on the road. Regardless, you should ensure to take your vehicle to the workshop once it begins to have drivability issues.

Poor drivability can be caused by a bad camshaft position sensor that cannot transmit the data quickly. Slow signal and data transfers will cause uneven fuel injection and ignition timing that will cause your car to lose power, stall, accelerate poorly, or sputter. A small change in the ignition timing (even by milliseconds) will lead to drivability issues.

Poor fuel economy

The fuel injection timing is important when it comes to fuel economy. If the fuel injection takes a long time, a lot of excess fuel will be put into the chamber leading to waste. On the other hand, short fuel injection will do the opposite but this is less concerning than having excess fuel in the combustion chamber.

Excess fuel can lead to serious damages to the engine since gasoline does not compress like air. There will be a build-up of excess fuel in the chamber that can cause engine knocking.

If you start experiencing bad fuel economy, that is a sign to take your vehicle to the mechanic’s shop since a bad camshaft sensor may be the cause.

Problems with the transmission

Delayed sensor data transfer to the PCM will also affect the transmission system. The transmission system relies on the camshaft position sensor to help the system actuate the transmission shift solenoids.

A bad camshaft position sensor may eventually prevent the gears from shifting leading to a locked transmission.

You can get rid of this symptom temporarily by shutting off the engine, waiting for a few minutes, and then restarting it. The only permanent solution to this problem is to replace the sensor.

What causes a camshaft sensor to go bad?

Accidents or normal wear and tear can cause the camshaft position sensor to malfunction.

Wear and tear

It can fail due to use over a long time, moisture, water damage, and oil build up on the engine. This sensor continuously operates when the engine is on. Whether driving or not, if the engine is on, the CMP is working and can get sworn down. To monitor camshaft speed, it must be functioning, even when the vehicle is parked. The camshaft rotates if the engine rotates. The parked position only disengages the gears to the transmission. The engine is still turning when the vehicle is parked.

Accidents

If the vehicle is involved in an accident, it can cause damage to the sensor. If the sensor wires are damaged, the impact can cause the CMP to stop working correctly. Sometimes an oil leak due to a bad head gasket or defective or loose oil cap can cause the sensor’s signal from the wires to be interrupted. In some cases, the camshaft sensor can go bad as a secondary problem related to an issue with another engine component. If the scan tool indicates a problem with the camshaft sensor, take care of it right away.

Other causes

- Oil embedded in the engine.

- Internal short circuits due to corrosions or accidents.

- Break in the encoder wheel

- Interruption in connection to the control unit

- Oil leaks due to bad head gaskets.

- Malfunctioning oil caps can interrupt camshaft position sensor system signals.

- Failure of other engine components that cause mechanical damage or signal interruptions.

Read more: What Transmission Do I Have

Can low oil cause the camshaft position sensor to go bad?

Low oil may cause the camshaft position sensor to go bad but not directly. Low oil levels will eventually cause the engine to overheat and the excessive heat in the engine will cause mechanical damages to the sensor,

Heat is not the only cause. The low oil levels will affect the oil pressure in the engine bay not to mention lubrication of the components. This will affect the lifters, camshaft variable timing actuators, and the camshaft components. Low oil levels will also affect other components in the combustion chamber which will in turn damage the camshaft position sensor.

You will need to use an OBD 2 scan tool to be able to get the specific cause of the problem. A mechanic will be more equipped to diagnose the issue more accurately and it is recommended you let the professional handle this problem since it is critical.

Is it safe to drive with a bad camshaft sensor?

You can safely drive your vehicle even though it has a bad camshaft sensor but you will experience some drivability issues that may be cause for concern. You will have problems shifting gears which will affect the vehicle’s performance when you want quick moves and fast reactions on the road.

The engine stalls and vehicle jerking are also very dangerous especially when you are on the highway. You may be able to evade any safety concerns at slow speeds and keep safe distances between you and other vehicles. Additionally, the poor fuel economy that comes with a bad camshaft sensor will be inconvenient and cause other engine problems.

The acceleration may be limited to less than 30 miles per hour if the damage has been there for a long time. We probably do not need to say how efficient acceleration is important when driving on a busy road.

How to test a camshaft position sensor with a multimeter?

The camshaft position sensors can be classified into 2 wire types or 3 wire types. The wire type refers to the number of wires in the connectors that are found on the camshaft position sensors. These two types of camshaft position sensors are tested in two different ways that we will discuss below.

Testing a two-wire camshaft position sensor

Start by setting the multimeter to AC Volts instead of DC volts. Use your vehicle’s manual to locate where the camshaft position sensor is mounted. Make sure you have some to assist you since these two methods require two individuals to make it work.

Have the other person turn on the ignition without starting the engine. Use the two multimeter probes to check for the flow of electricity through the two sensor wires. Take one probe and ground it and use the other one to touch each one of the sensor wires. If you fail to notice any current flow through the wires, the sensor circuit may have failed.

Proceed to have the other individual start the engine this time. Use one multimeter probe to touch one of the sensor wires and use the other probe to touch the second sensor wire. Look at the multimeter reading and compare the notes with the specifications on the vehicle manual.

If there is no reading, the sensor is bad and has to be replaced. If there is, ensure the reading only fluctuates between 0.3 volts to 1 volt of the manufacturer’s standard reading.

Testing a three-wire camshaft position sensor

Start by setting the multimeter to DC Volts instead of AC volts. Use your vehicle’s manual to locate the ground, power, and signal wires of the three-wire camshaft position sensor. Ensure you have some to assist you. Let the helper turn on the ignition without starting the engine.

Use the black probe of the multimeter to touch the ground wire and use the other probe to touch the power wire. Let the other person start the engine as you proceed to use the red probe to touch the signal wire and the black probe on the ground wire.

Compare all the readings to those that come in the manufacturer’s vehicle manual. In case the readings do not show or are lower than the standard then the sensor has malfunctioned and needs to be replaced.

How to tell which camshaft sensor is bad?

You can tell which camshaft sensor is bad by using the above method that entails a multimeter. You may also unplug the sensors to take a look at the physical damage, any corrosion, or deposits that are not supposed to be present.

The signs and symptoms that are associated with a faulty camshaft are also a clear way to pinpoint the issue. The check engine light will be able to notify you of the problem and you can use the OBD 2 scan tools to check for the specific trouble codes. The manufacturer-specific codes will be able to notify you if the issue is in the sensor or the associated circuit.

What to do after replacing the camshaft sensor?

The first thing you have to do after replacing the camshaft sensor (or fixing any car issue) is to use the OBD scan tool to erase the associated trouble codes. You may also opt to drive the vehicle for about 10 minutes so that the check engine light can turn off automatically indicating the issue has been fixed.

Replaced camshaft position sensor but still get code: Why?

If the camshaft position sensor was the issue, replacing it will fix the problem. You will still get the trouble code if the problem was not the sensor but other components and wiring on the camshaft position sensor circuit.

Make sure to check the specific code to have a specific answer to where the problem is. Moreover, you should make sure you perform the multimeter tests to see if the circuit or the sensor is the problem. Diagnosing the issue correctly is the only way to get rid of it permanently.

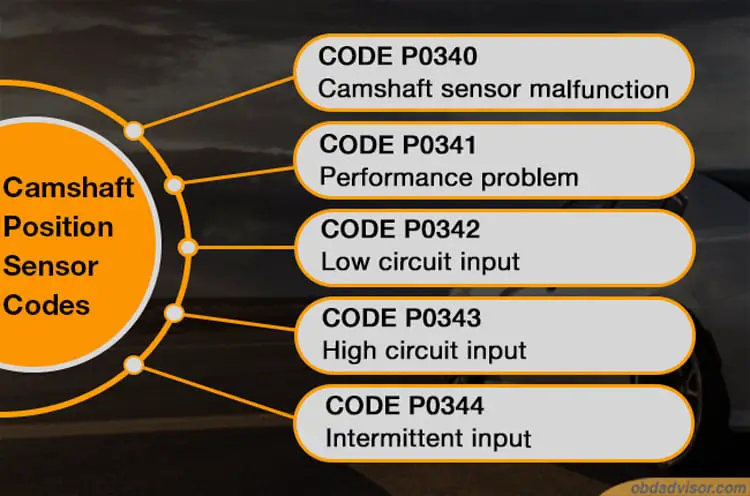

Bad camshaft position sensor OBD2 codes

CODE P0340 – will come up, which indicates a camshaft sensor malfunction. When this code appears on a scan tool, it suggests a bad sensor or other related issues such as the harness wiring.

CODE P0341 – performance problem

CODE P0342 – Low circuit input

CODE P0343 – High circuit input

CODE P0344 – Intermittent input

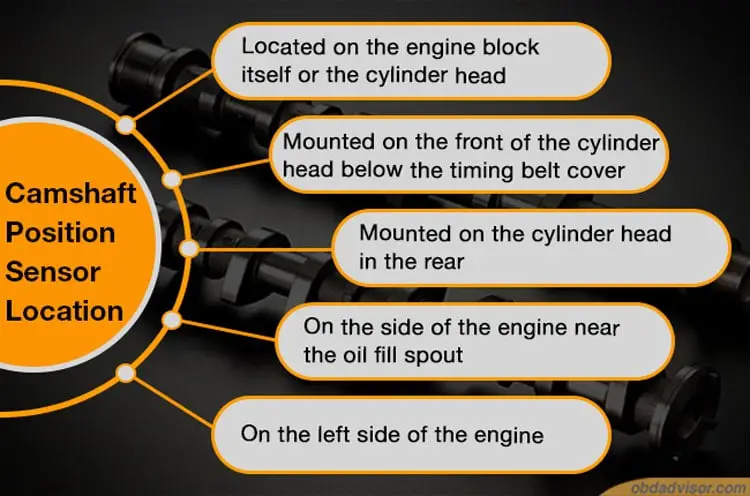

Camshaft Position Sensor Location

The best practice is to look in the engine service manual to locate the camshaft position sensor. Most if not all vehicles are located on the engine block itself or the cylinder head. In some cars, the CMP might be:

- Mounted on the front of the cylinder head below the timing belt cover.

- Mounted on the cylinder head in the rear.

- On the side of the engine near the oil fill spout.

- On the left side of the engine.

If you don’t know for sure, refer to the engine service manual. Don’t guess. It can be in locations that are difficult to get to.

How to replace camshaft position sensor

Step 1: Remove the harness wires

Step 2: Remove the camshaft sensor with a 10 mm wrench. Check for chips and damaged cam sprockets.

Step 3: Insert new camshaft sensor

Step 4: Replace harness

Conclusion

The failure of a camshaft position sensor is a critical issue that requires you to act promptly since it can lead to engine failures and unsafe drivability issues. Over time, the sensor will weaken further and prevent the engine from starting due to the failure to transmit data signals to the PCM.

The failed/weak signals will cause the PCM to stop injecting fuel into the combustion chamber and fail to time the timing rotor. The engine will stop working since there isn’t any electronic detection to activate the processes. This can be catastrophic while on the road leading to accidents and other inconvenient scenarios.

Read more: Bad CRANKshaft position sensor: symptoms, causes, and fixes