This article will focus on Crankshaft Position Sensor symptoms—arguably the most crucial sensor in your vehicle.

The vehicle’s onboard computer, also known as the Electronic Control Module (ECM), monitors and analyzes data from the sensors then translates its findings into codes. Compression in the cylinders, engine temperature, fuel consumption, and more are all monitored with sensors. When the orange engine warning light on the dash lights up, it means there’s a problem. What’s going on, and how do you repair the problem?

One reason the check engine indicator light comes on could be a faulty Crankshaft Position Sensor (CPS). Some of the symptoms are the vehicle overheats or stalls, and you don’t get the power you used to. Another indicator of a faulty Crankshaft Position Sensor is your vehicle will not restart until the engine is cold. These are just a few symptoms.

Getting started, remember to follow proper safety precautions, and use the right tools for the job.

What is a crankshaft position sensor, and what does a crank sensor do?

The crankshaft position sensor is a device that has a coil wrapped around it that generates a low voltage signal. The device transmits data as an electronic signal to the ECM about the crankshaft position as certain functions occur. This data analyzes when essential functions happen, such as injecting fuel into each cylinder, compression, and ignition that creates engine RPM. The sequence of the timing of all those functions as well as others determines how the engine performs.

The Crank Sensor will generate data that measures engine RPM as it passes the sensor. This information will be used to calculate if the fuel injectors’ firing order and other essential functions like the order that the injectors fire happen in the right order as the engine was designed for them to do.

Where is the crankshaft position sensor?

The crankshaft position sensor is on the bottom of the engine between the engine and the transmission. Although the crank position sensor is located between the engine and the transmission, the exact location depends on the manufacturer. On some engines, it might require the removal of a tire to get to it. Keep in mind if you need to jack the vehicle up. Make sure you have all the safety procedures in place first.

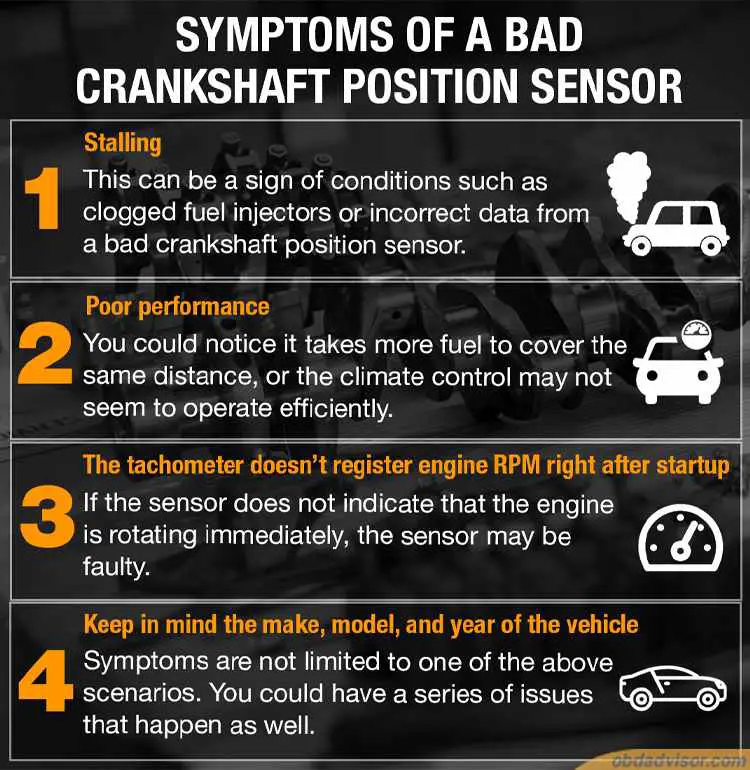

Symptoms of a bad crankshaft position sensor

Stalling

When the engine stalls, it is a clear indication of a problem. When you stop in traffic or begin a trip, the vehicle starts then shuts down. Engine stalls can be a consequence of conditions such as clogged fuel injectors, a faulty fuel pump, or incorrect data from a bad crankshaft position sensor to the engine control module.

Poor performance

This is a general term with specific conditions. It could be that you notice it takes more fuel to cover the same distance as it did in the past. The climate control may not seem to operate as efficiently as it used to, or sluggish acceleration.

The tachometer does not register engine RPM immediately upon startup

Your vehicle’s manufacturer designs it with specific tolerances that allow for peak performance. If the sensor does not indicate that the engine is rotating immediately, the sensor may be faulty.

Keep in mind the make, model, and year of the vehicle

Crankshaft position sensor symptoms are not limited to one of the above scenarios. You could have a series of issues that happen as well. The vehicle might not start immediately, never stalls but hesitates when you accelerate.

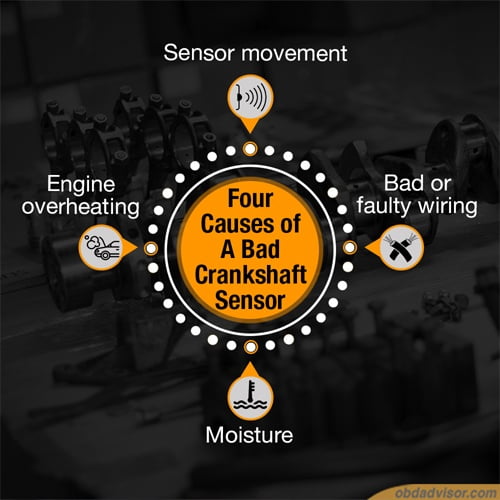

What causes a crankshaft sensor to go bad?

Some things that can cause the Crankshaft sensor to fail include:

Sensor movement

Over time the vehicle is subject to different road conditions and issues. One issue that can cause crankshaft position sensor movement Is hitting the barrier in parking lots and road debris while driving. These conditions can cause the sensor to become loose.

Bad or faulty wiring

There is no absolute formula to indicate when your vehicle might begin to experience crankshaft position sensor problems. As cars get older, it is more likely to happen.

Engine overheating

A simple routine function like not changing the oil and other engine coolants, can cause the vehicle to run hot.

Moisture

As a car gets older, things can tend to lose the torque due to constant engine vibration. If the bolt that holds the crankshaft position sensor come loose moisten might seep in.

Bad crankshaft position sensor codes

The code that indicates a problem include:

- P0335 -The engine ECM or electronic control module has not detected the Crankshaft Position Sensor on engine start up.

- P0339 – Possible problem could be exterior damage to the sensor. The solution looks for external damage, including wiring issues.

- P0016 – Problems between the timing of the crankshaft and the camshaft sensor. The possible problem is most likely because the crankshaft position sensor’s code does not match the camshaft position sensor’s code.

- P0017 – Problem between the crankshaft and exhaust camshaft. The problem is most likely that the two sensors are not in sync with each other.

There are additional codes that indicate other issues. However, they will all involve the crankshaft position sensor. Diagnosis of problems in the crankshaft position sensor system takes skill and understanding of automotive electrical and mechanical systems before you can tackle a task like this.

Crank position sensor test

Use a diagnostic scan tool with a relearn function. Plug it into the vehicle’s onboard computer, start the car, then see if code P0335 comes up. This code will indicate there is a crankshaft position sensor problem. If you do get a code P0335, remove the sensor, then check the voltage. One primary indicator of crankshaft position sensor symptoms is the voltage is not about 12 volts.

This is an indication the sensor is faulty and you need to replace it. Driving on rough roads or road debris damage can hit the engine and cause damage to the sensor in a new vehicle with very low mileage. If the crankshaft position sensor needs replacing, do it immediately. Remove and replace the old sensor.

After you replace it, reset the sensor, then clear the codes to test the new sensor. After you have done this, start the car. If the repair were a success, you would not see any engine warning light, and the vehicle should start immediately. Also, as mentioned above, check the voltage. The diagnostic device will not register any codes at all. Once the crankshaft position sensor has been replaced, the vehicle should perform better.

The crankshaft position sensor helps to ensure your vehicle runs according to the manufacturer’s specifications. The crankshaft position sensor must work correctly, so the other essential functions perform as they were designed to do. The fuel injectors work out the firing time based on the piston’s position in the cylinder, which is based on the data analysis of the crankshaft position sensor. If the engine cannot get a correct signal to the cylinders, engine performance problems begin to happen. The new sensor will eliminate this problem.

The engine’s speed must also be accurate, so the electronic control module gets correct data that correlates with how fast the vehicle is traveling. When this is inaccurate, the injectors could have errors in the calculation based on incorrect data, causing the engine to stall or shut down. That is why it is critical to test and replace the crankshaft position sensor if necessary.

How to fix a bad crankshaft sensor?

Remove and replace the bad crankshaft position sensor. This is a self-contained device that must get replaced if damaged. The crank position sensor will most likely be held in place with a 10 MM bolt. The proper tool is usually the 10 MM short socket. Before installing the new one, slightly lubricate it and the O ring with engine oil and put it back in. After you have re-installed the new crank position sensor, start the car. If you do not get a code, you are good to go. Reset the computer by selecting erase codes in the diagnostic scan tool, then select yes. If the repair were a success, you would not see any engine warning light, and the vehicle should start immediately.

How to start a car with a bad crankshaft sensor?

The vehicle might start after the engine cools down. However, in some cases, the car will not be able to be restarted. Overall, it is not a good idea to continue to start the engine with a faulty crankshaft position sensor, if it starts at all. Manufacturers install sensors to alert you to a problem.

A vehicle can run for hundreds of thousands of miles if maintained properly. Anytime the check engine light comes on, it indicates an issue that needs further analysis. The Crankshaft Position Sensor symptoms can only be addressed when the vehicle is further analyzed. The crankshaft is the essential backbone of the engine. Without a crankshaft, the power produced in the cylinders can’t be converted to forward motion.

Take care of the vehicle by using the recommended lubricants and follow maintenance schedules. If the car hits something while on the road, do a thorough inspection of the undercarriage ASAP.

How serious is the problem?

Anytime the check engine indicator comes on, it’s a problem. The purpose of the light is to warn you of a problem. Check your owner’s manual to see if it has a section devoted to sensors in general and crankshaft position sensors specifically. This is a severe problem.

The only way to know what has caused the problem is to do a diagnostic test, which will give you a code that corresponds to a specific problem. You can probably drive a vehicle with the ‘Engine Oil Change Due’ message on for a thousand miles, even that is pushing it and might not cause a problem. Eventually, you need to change the oil. On the other hand, you must change a bad crankshaft position sensor as soon as possible.

The orange check engine symbol is a start in the process to determine if you have a problem and how serious the problem might be. If it comes on, the vehicle most likely has a serious problem, and you need to address it as soon as possible. In addition to crankshaft sensor symptoms, there might be other issues such as emission control sensors.

Think of it as the manufacturer’s fail-safe to let you know that you should address the issue. The ECM displays a code that needs to be diagnosed immediately. As mentioned before, road condition, missed maintenance, and vehicle age, all factor into a possible crankshaft position sensor malfunction.

This problem can cause other issues, such as engine timing issues. The crankshaft position sensor needs to be in proper working order, so your vehicle performs as it was designed to perform all the time. If ignored, more problems could affect your vehicle’s performance, up to and including permanent damage.

Read more: OBD2 Software: Top 21 Packages for Mac Windows Linux in 2021