A couple of decades ago, there were almost no electronic components in cars. As automotive technology evolved, transistors began to be used. More sensors were installed on cars to constantly create more power while keeping emissions low and fuel efficiency as good as possible. After a while, car manufacturers were left facing a new problem: they needed a central control module to make sure all these new sensors and electronic components could communicate with each other and control the different actuators accurately. This was when control modules were created.

In recent years, the number of onboard modules in cars exploded. There is now a control module dedicated to almost every system on your vehicle, and the most important one is, without a doubt, the powertrain control module. This article aims to explain how PCM works, what they are used for, what happens when it goes awry, and how much is the average replacement cost.

What Is A PCM?

The powertrain control module is the central module of your vehicle. It receives and processes all the signals sent by the various sensors related to the engine’s powertrain. Besides, it also coordinates all the other modules, like the transmission control module and the body control module, and makes sure they “talk” to each other.

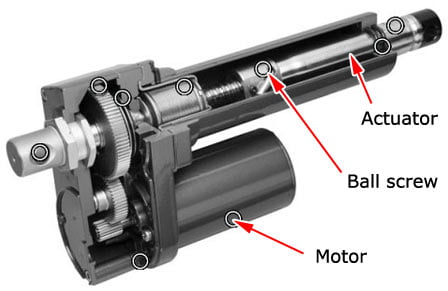

To put it simply, the PCM is basically like the processor in your PC. Each sensor on the engine is connected to a module-specific to each system. Once the information reaches the sub-system module, it quickly processes the data. Then sends the calculations to the PCM, which will, in turn, send a signal to activate various actuators to make sure the engine works correctly.

For example, the O2 sensor on your exhaust system measures the air/fuel ratio of the exhaust fumes. If the air/fuel mixture is too rich, the PCM will reduce the injector’s opening time to bring it down. If it’s too lean, it will increase it to maintain a stoichiometric ratio at all times.

It’s the same with most other sensors. The PCM receives data from the camshaft sensor to know which valve is open or closed and the data from the crank to know the piston’s exact position. It can then adjust precisely the moment when the spark plug will ignite the air/fuel mixture.

The amount of data the PCM has to process and the number of actions it can take to adjust and fine-tune the engine’s operation increases with every new car model. On recent vehicles, the PCM can independently control the spark timing advance, each intake’s opening, and exhaust valves.

Not to mention most recent innovations like autonomous driving, head-up displays, onboard wifi as well as more advanced safety systems like pre-collision braking and external airbags. Of course, each of these systems has a dedicated control module, but all of them are controlled by the PCM’s, the main processor.

How Does It Work?

A PCM includes various components, each having their purpose:

- The processor: Just as in any computer, the processor is the component making everything work together. It calculates and processes the signals coming in and sends signals to the actuators.

- The memory: This is where the program tells the processor what to do with the data and what action needs to be taken. Each vehicle has different programming based on the internal components of the engine and how the manufacturer intended it to work. The memory decides the injection time, the spark timing, whether the car will accelerate like a sports car, or will it be more fuel-efficient instead. This is what tuners will modify when they say they “chipped” their car. Recent PCM uses FLASH memories of the same type as used in USB keys. Flexible and easy to reprogram, they can be reprogrammed by the manufacturer in case of a Nationwide recall to correct various mistakes in the OEM programming.

- Input/Output circuits: These circuits are used to either read data or send data to various components. The input circuits receive the sensors’ data and transform the signals into binary code so the processor can read it. Output circuits are used to send a signal back to adjust the position or operation of different actuators.

How Important Is The PCM To Your Car/Truck?

The PCM is what makes everything work. It is, therefore, vital to your vehicle. Just imagine what would happen if you were to remove the processor from your PC. The monitor would still light up, the signal from the mouse would still reach the computer, the keys from the keyboards could still be pressed down, but the computer would do nothing at all. A computer needs a processor to understand the signal it receives and project it on the screen. It’s the same with your car.

Without a PCM, the starter could still theoretically spin when you turn the ignition key to the RUN position, the fuel pump would still pump fuel if supplied by power, and the radio could still play music. Unfortunately, when the key is turned to the RUN position, the ignition barrel sends a signal to the PCM, which will, in turn, close the starter relay, making it start the car. The PCM also controls the fuel injectors’ opening, the ignition system, and the fuel pump’s power circuit. Without a PCM, not only wouldn’t the fuel pump send fuel to the engine, but the injectors wouldn’t open, and the spark wouldn’t happen anyway. And while the radio only needs a 12v input to operate, the signal to turn on the car stereo circuit is sent by the body control module, which is operated by the PCM.

It’s the same thing with lights, power windows, power door locks, power seats, the heating system, the ABS, etc. Even the rear window defogger and the 12v outlet are ultimately controlled by a module somewhere on most recent vehicles. The only components not controlled by a control module are the strictly mechanical ones like the suspension system, for instance. And, even then, they are often monitored by sensors to act on other systems.

A good example of this is the steering system. While the steering columns, rack & pinion, and tie rods were traditionally mechanical systems, most recent vehicles now have sensors to monitor the angle of the tires and the steering position. On vehicles equipped with autonomous driving features, small electrical motors are installed somewhere on the steering system. A control module will use the camera data to understand where to steer to and output circuits to operate the different steering motors. As a general rule, remember that if the component is electric, it’s probably controlled by the PCM at some point.

Symptoms Of Powertrain Control Module Malfunction

Since the PCM controls everything on your vehicle, the list of symptoms of a bad PCM is pretty much endless. When a PCM goes bad, it will either stop reading and processing signals or stop outputting a control signal. It can mean anything from a bad adjustment of a component to a component not working at all.

Let’s use the fuel system, for example. If an input circuit used to process the O2 sensors signals were to stop working, the PCM might start injecting too much or not enough fuel to the engine. Since it can’t understand the data coming from the O2 sensors anymore, the PCM has no idea if the engine is running rich or lean and won’t keep the air/fuel ratio steady. If an output circuit is faulty, the PCM might stop sending a signal to open an injector. Or the PCM might not close the fuel pump circuit, and no fuel will reach the injectors at all.

The same thing may happen with the power window system too. If the PCM can’t process the signals, the window might stop half-way down. If the memory is corrupted, the processor will have no idea what to do with the input signals coming from the window switch. If, on the other hand, there’s something wrong with the output circuits, the PCM might be receiving the signals alright, but the window will stop moving altogether. And so on with all the other systems on the vehicle.

Luckily, a faulty PCM is not a frequent condition. When a component stops working on your car, the last thing to suspect is the powertrain control module. When troubleshooting a “power window not working” condition, the first thing you’ll do is to test for power and ground. While the PCM effectively controls the body control module providing the power, if no power is coming to the motor, the problem most is most likely coming from a faulty window switch or open circuit condition instead.

If you’ve ever used a troubleshooting chart before, you’ll notice that the box “replace the PCM” is always the last one at the very end of the chart. That means that you should always test all the other components and circuits first, and if, and only if no other problem is found, you should start suspecting a faulty powertrain control module.

How To Replace A PCM

Replacing a PCM is surprisingly easy, considering if you can find it in the first place. Depending on the kind of vehicle you drive, that may or may not be complicated. Hyundai Accents, for example, used to have their PCM hooked to the air intake box. Some others, like Chevrolet Cavaliers and Sunfires, had their PCM hidden behind the FL inner fender panel. On old Honda Civics, it was located under the carpet on the passenger side. In all cases, the most complicated part is usually to get to it. You might have to remove trim panels, fuses boxes, wiring, and other various components to reach it as manufacturers tend to place it in the most practical place every time. When it’s done, replacing a PCM is as easy as 1, 2, 3. Simply keep the ignition key out of the ignition barrel, unplug the connectors and remove the fasteners, usually between 2 and 4. Reinstalling the new one is just as easy. Plug back the connectors, screw back the fasteners and reinstall everything in the reverse order.

The most important thing to remember, though, is that a PCM rarely breaks for no reason. It might have burned or blown out because of a power surge, a short circuit, water infiltration, or any other reason. Keep in mind that replacing it without fixing the problem will only result in blowing up a second PCM. Always make sure that the problem has been fixed before plugging in the new PCM, or you might end up with a pretty hefty bill.

How Much Does It Cost To Replace A PCM?

Once again, the answer to that question will depend on the kind of vehicle you own. There’s no real correlation between the car manufacturer and the PCM cost, but, generally speaking, the more expensive the vehicle, the more expensive the PCM. This is usually because luxury vehicles have more onboard systems and more electronic features resulting in more sub-system modules requiring a more powerful PCM. However, just like with any other automotive parts, some are more expensive than others for no apparent reason. While most power-window switches cost around $150, the main switch for a Hyundai Azera cost over $700 for a pretty standard switch design. Honda Civic alternators were also famously expensive in the auto mechanic world a couple of years ago, selling for at least 2 to 3 times more than any other entry-level sedan on the market for what appeared to be a conventional alternator.

When it comes to PCMs, they can cost anywhere between $500 to $3,000. For instance, an OEM control module for a 2015 Honda Accord EX costs around $600 while the same component for a 2014 Porsche Cayenne Hybrid costs more than $2,600. In general, though, a powertrain control module for most vehicles built by the leading manufacturers like Toyota, Mazda, Ford, GM, Honda, Hyundai, Kia, etc., will cost less than $1,000. There is also a considerable price difference between OEM control modules and aftermarket ones. If your vehicle’s PCM needs to be replaced and you find out that most models from auto parts stores are way out of your budget, you can also look for PCM specialists who can reprogram or rebuild it. A rebuilt PCM will usually cost less than half the aftermarket price one and almost three times less than a brand-new OEM model.

It’s also important to keep in mind the labor cost of having your PCM replaced. On most vehicles, 2 hours should be more than enough for a certified technician to remove all the trims, reach the PCM, replace it and reinstall everything. Depending on your auto repair shop’s labor rate, the labor cost might be more or less expensive. Dealers tend to charge more than auto repair shops but also know your car by heart. The mechanic working on your car may have replaced many control modules on the same vehicle in the past and may reach the PCM in less time than another less specialized mechanic. Another essential point to consider is the time needed to reflash the new PCM and code your transponder key to match the factory immobilizer settings. Other settings may also need to be paired and programmed to match the new powertrain control module with your vehicle after replacement, adding to the overall labor cost.

Last Words

Powertrain control modules are essential to your engine’s good operation and, therefore, tend to be quite difficult to troubleshoot and expensive to replace. Luckily, most PCM will last longer than the vehicle in which they are installed. Suppose you are unfortunate enough to have a problem with your control module or suspect that your vehicle’s electrical problems may be related to a PCM error. In that case, you are often better off bringing your car to a certified mechanic right away. An incorrect, faulty PCM diagnostic will often end up being a lot more expensive than asking your mechanic for help anyway. When in doubt, it’s always cheaper to play safe and seek the help of a more experienced person, and, in most cases, that person is often a trustworthy auto mechanic.