P2610: ECM/PCM Internal Engine Off Timer Performance

Is your scanner showing P2610?

No worries. We'll show you what it means and how to deal with it.

P2610: ECM/PCM Internal Engine Off Timer Performance

OVERVIEWWhat Does The P2610 Code Mean?

When I encounter a stored code P2610, it tells me that a malfunction has occurred, in the engine control module (ECM) or powertrain control module (PCM), concerning an inability to determine whether or not the engine has been shut off; and more specifically for how long the engine has been shut off.

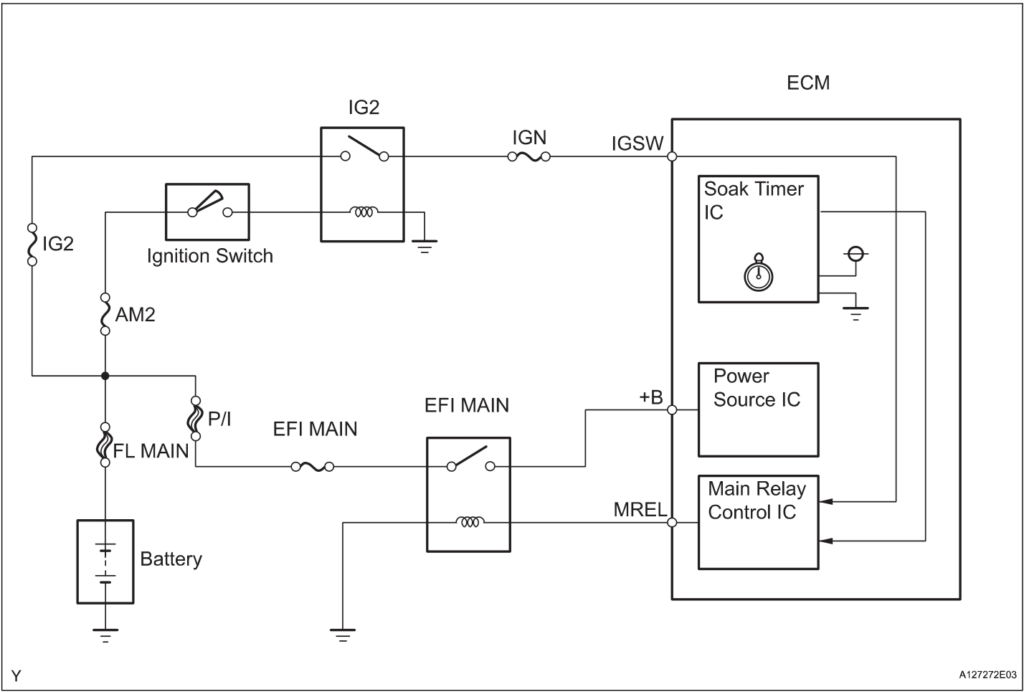

The engine controller, whether it is referred to as an ECM or a PCM, uses input signals from the engine to determine whether or not the engine is running.

Among the engine control indicators used to accomplish this are engine RPM (crankshaft position sensor), fuel pressure sensor, and primary ignition system voltage. If the ECM/PCM fails to detect a signal from one of these (or any one of a number of other) indicators signifying that the engine has been shut off, when switched (present only when the ignition switch is placed in the on position) voltage is not detected, it may not discern that the engine has been shut off.

The ECM/PCM internal engine off timer is critical to monitoring ignition cycles which help to calculate fuel delivery and ignition timing, as well as transmission shift patterns. If the ECM/PCM fails to declare the engine shut off and begin monitoring time between ignition cycles, a code P2610 will be stored and a malfunction indicator lamp may be illuminated. Typically, multiple ignition cycles (with a failure) will be required for malfunction indicator lamp illumination.

P2610 wiring diagram

What Are The Symptoms Of The P2610 Code?

Symptoms of a P2610 code may include:

- Initially, no obvious symptoms will likely appear

- Diminished engine performance

- Decreased fuel efficiency

- Eventually, engine drivability symptoms may also be exhibited

What Are The Potential Causes Of The P2610 Code?

Potential causes for this code to set are:

- ECM/PCM programming errors

- Defective ECM/PCM

- Open or shorted wiring or connectors

- Faulty crankshaft position sensor (CPS) or shorted CPS wiring

How Serious Is This P2610 Code?

Since so many underlying factors depend upon ECM/PCM internal engine off timer performance, this code should be addressed with some degree of urgency.

How Can You Fix The P2610 Code?

Locate a technical service bulletin (TSB)

A good starting point is always to check for technical service bulletins (TSB) for your particular vehicle. Your issue may be a known issue with a known fix put out by the manufacturer and can save you time and money during diagnosis.

In order to diagnose a stored code P2610, you will need a diagnostic scanner, a digital volt/ohmmeter (DVOM), and a reliable vehicle information source (such as All Data DIY).

If there are one or more CPS codes present, diagnose and repair those before attempting to diagnose a stored P2610.

Retrieve all stored codes

You will be well served to connect the scanner to the vehicle diagnostic connecter at this time. Retrieve all stored codes and freeze frame data and write this information down; it may be helpful, especially if the P2610 proves to be an intermittent code.

Now, clear the codes and test drive the vehicle to see if the P2610 is reset. If it is reset, reconnect the scanner and observe CPS and engine RPM data using the data stream display. Focus on CPS and RPM readings with the key on and the engine off (KOEO). If engine RPM readings indicate anything other than 0, suspect a defective CPS or shorted CPS wiring. If CPS and engine RPM data appears normal, continue with the diagnostic process.

Use the DVOM to observe ignition coil primary voltage

Use the DVOM to observe ignition coil primary voltage with the ignition in the off position. If ignition coil primary voltage remains above five-volts, suspect a wiring short (to voltage) in this system. If voltage is at 0, continue with your diagnosis.

Utilizing your vehicle information source, determine the precise parameters used by the ECM/PCM to indicate that the engine has been shut off and an ignition cycle has ended. Once you have made this determination, use the DVOM to test all individual circuits for related components.

Test circuit resistance with the DVOM

To prevent ECM/PCM damage, disconnect all related controllers prior to testing circuit resistance with the DVOM. Repair or replace defective circuits as needed and retest the system. Keep in mind that no repair can be declared successful until the ECM/PCM enters readiness mode. To accomplish this, just clear the codes (after repairs are performed) and drive the vehicle as usual; if the PCM enters readiness mode, the repair was successful and if the code is reset, it was not.

If all system circuits are within specifications, suspect a defective PCM or a PCM programming error.

Additional diagnostic notes:

- Failure to address a code P2610 could result in catalytic converter damage (among other things)

- Don’t assume that the PCM is at fault, system wiring malfunctions are common

- Use your vehicle information source to match technical service bulletins and/or recalls to the code/s and symptoms in question

Recommended Parts

Below are some recommended auto parts to help you address the trouble code affecting your vehicle and get it running smoothly again:

>>> WORKPRO 582-piece Crimp Terminals, Wire Connectors, Heat Shrink Tube, Electrical Repair Kit

>>> ECU

Note: During the purchasing process, please check carefully whether the part you want to buy fits your car!

Check This Video For Reference

Reference Sources

ENGINE CONTROL SYSTEM [GASOLINE ENGINE (V-6)] SERVICE MANUAL for P2610 – Pages 875-876.